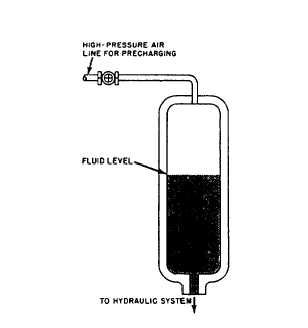

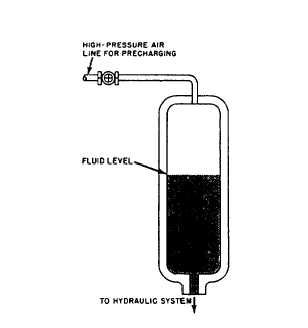

port on the bottom and a pneumatic charging port

at the top (fig. 9-8). This type of accumulator is

used in some airplane elevator hydraulic systems

where several thousand gallons of fluid are needed

to supplement the output of the hydraulic pumps

for raising the elevator platform. The direct

contact between the air or gas and the hydraulic

fluid tends to entrain excessive amounts of gas

in the fluid. For this reason, direct contact

accumulators are generally not used for pressures

over 1200 psi. The use of this type of accumulator

with flammable fluid is dangerous because there

is a possibility of explosion if any oxygen is

present in the gas, and pressure surges generate

excessive heat. For this reason, safety fluids are

used in this type of installation.

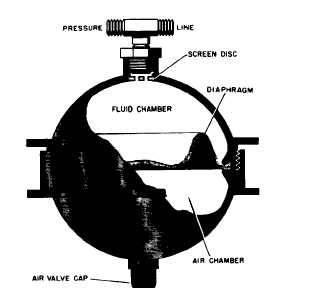

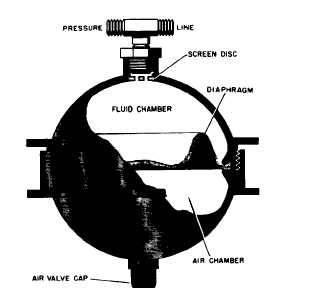

DIAPHRAGM ACCUMULATORS

The diaphragm-type accumulator is con-

structed in two halves which are either screwed

or bolted together. A synthetic rubber diaphragm

is installed between both halves, making two

chambers. Two threaded openings exist in the

assembled component. The opening at the top,

as shown in figure 9-9, contains a screen disc

which prevents the diaphragm from extruding

through the threaded opening when system

pressure is depleted, thus rupturing the dia-

phragm. On some designs the screen is replaced

by a button-type protector fastened to the center

Figure 9-8.—Direct-contact gas-to-fluid accumulator.

Figure 9-9.—Diaphragm accumulator.

of the diaphragm. An air valve for pressurizing

the accumulator is located in the gas chamber end

of the sphere, and the liquid port to the hydraulic

system is located on the opposite end of the

sphere. This accumulator operates in a manner

similar to that of the bladder-type accumulator.

FILTRATION

You have learned that maintaining hydraulic

fluids within allowable limits is crucial to

the care and protection of hydraulic equipment.

While every effort must be made to prevent

contaminants from entering the system, con-

taminants which do find their way into the system

must be removed. Filtration devices are installed

at key points in fluid power systems to remove

the contaminants that enter the system along

with those that are generated during normal

operations.

Filtration devices for hydraulic systems differ

somewhat from those of pneumatic systems.

Therefore, they will be discussed separately.

The filtering devices used in hydraulic systems

are commonly referred to as strainers and filters.

Since they share a common function, the terms

strainer and filter are often used interchangeably.

As a general rule, devices used to remove large

particles of foreign matter from hydraulic fluids

are referred to as strainers, while those used to

remove the smallest particles are referred to as

filters.

9-7