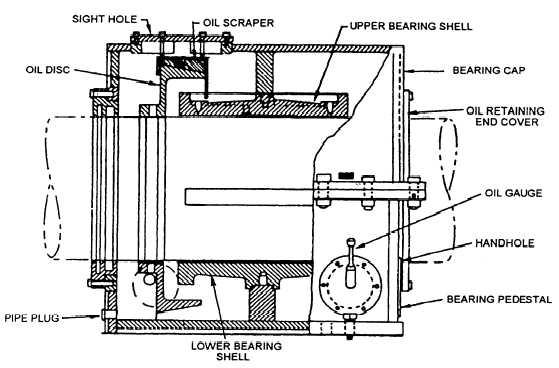

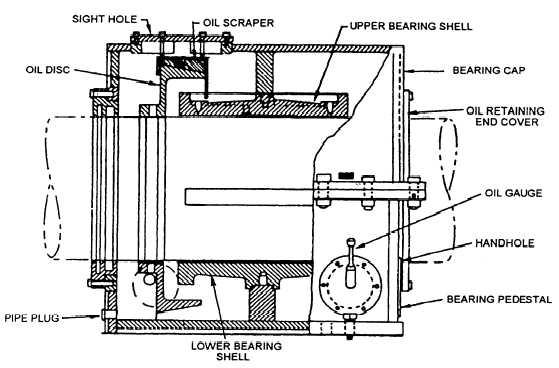

An oil disc (ring) clamped to the shaft is used in each

bearing to deliver oil to the upper bearing and journal

surfaces. As the disc rotates, it picks up oil from the

bearing reservoir and carries it to the oil scraper on the

upper shell. The scraper removes oil from the disc and

directs it to the upper bearing lining. A clear sight cover

on the bearing housing allows visual confirmation of the

oil disc operation. Figure 3-7 shows a typical disc-oiled

line shaft bearing.

All bearing pedestals have an oil level rod and an

oil reservoir thermometer for checking oil level and

temperature. A resistance temperature detector (RTD)

is installed in the lower bearing shell of each

oil-lubricated bearing. The RTDs provide for remote

readouts of each bearing’s temperature on the digital

demand displays.

Clearances are taken with a depth micrometer

through a port in the upper bearing housing, which

contains the anti-rotation pin. The original installation

readings are stamped into the flat surface adjacent to this

port. You must take readings according to PMS

requirements or when an abnormal condition exists.

For information on maximum wear limits and repair

procedures, you should consult the appropriate

manufacturer’s technical manual and NSTM, chapter

244, “Shafting, Bearings, and Seals.”

STRUT AND STERN TUBE BEARINGS

Each propeller shaft extending aft of the stern tube

is supported by two struts, each containing a

seawater-cooled bearing. Figure 3-8 shows a typical

strut bearing.

Stern tube bearings are in constant contact with the

seawater surrounding the stern tubes. The clean

seawater that passes through the stem tube seals from

the ship’s seawater service system or firemain system

(in emergencies) also flows through the stern tube

bearings. Stern tube bearings are identical to forward

strut bearings. However, aft strut bearings are roughly

5 inches larger in diameter and twice as long as stem

tube bearings. Remember that stem tube bearings are

not remotely monitored.

PROPULSION SYSTEMS

The ship’s propulsion thrust is provided by

hydraulically actuated propellers. In the Gas Turbine

Systems Technician (Electrical) 3/Gas Turbine Systems

Technician (Mechanical) 3, volume 1, NAVEDTRA

10563, you were provided with a complete description

of propulsion systems and how they operate. As a gas

turbine supervisor you need to be knowledgeable and

experienced with a variety of gas turbine propulsion

Figure 3-7.—Disc-oiled line shaft bearing,

3-11