directly below that mark to get the total length of plate

to designate drill size. Some drill gauges may use a

needed to manufacture a 2-inch diameter cylinder or

combination of these designations to measure drill size.

6 1/4 inches. The total length of plate needed is 6 1/4

You will use these gauges when determining the correct

inches.

drill size for a given tap size.

Steel Plate and Sheet Metal Gauge

SQUARES

Steel plate and sheet metal gauges come in various

Working in an HT shop, you will use a square

sizes and uses, as shown in figure 5-7. You will use them

almost everyday. Squares are versatile instruments

extensively in sheet metal and structural metal fabrica-

that can be used to lay out lines and angles, to measure

tion to determine metal thickness or gauge. They are

distances, and for numerous other functions. There are

simple to use and extremely accurate. Simply fit the

numerous squares in use today, but only the steel

gauge to the plate so that the metal edge slides exactly

square and the combination square will be discussed

into the slot. The gauge should be snug, but do not force

in this section.

the gauge onto the metal. Gauge numbers are marked

on the front of the gauge with the corresponding deci-

Steel Square

mal reading on the back.

Steel squares (fig. 5-9) are used to lay out various

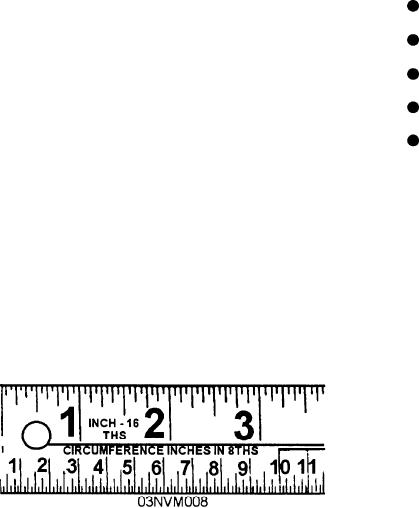

CIRCUMFERENCE RULE

angles and to check squareness or straightness of an

The circumference rule is a specialty rule that is

edge or surface. They are L-shaped tools that comes in

used to figure out the total length of plate needed for

12-, 18-, and 24-inch blade length. They are marked in

manufacturing cylindrical objects. The circumference

graduations of 1-16- or 1/8-inch divisions on the inside

rule looks similar to a regular steel rule but has two

and outside edge. The components of the steel square

scales marked on its face as shown in figure 5-8. The

are as follows:

top scale is an inch scale that is divided in sixteenths

BLADE--the longer leg of the square

of an inch and represents the diameter of an object.

The bottom scale is divided in eighths of an inch and

TONGUE--the shorter leg of the square

represents the circumference of a cylinder. The back

of the rule usually has formulas for calculating

HEEL--the outside comer

circumferences and shows areas and tables for laying

out measurements.

FACE--the inside edge of the square

Reading the circumference rule is a simple process

BACK--the outside edge of the blade

that requires no special math skills. First, determine

When using a steel square to lay out angles, place

the diameter of a cylinder in inches. Next, locate the

the tongue of the square on the base line with the

diameter on the top inch scale and read the

12-inch mark on the vertex of the desired angle. Mark

measurement directly below on the circumference

the vertical distance for the desired angle along the

scale to determine the total length of material needed

blade edge of the square. Connect the vertex to the

to fabricate the cylinder.

vertical height mark with a line. Some of the more

Using figure 5-8 as a guide, let's figure the total

common angles are shown in figure 5-10.

length of plate needed to manufacture a 2-inch

diameter cylinder. Locate the diameter, or 2 inches, on

Combination Square

the top inch scale, then read the circumference rule

The combination square (fig. 5-11) is a

multifunctional tool that can be used to lay out various

angles, measure height and depth, bisect a 90-degree

angle, and as a level. It consists of the following

components:

-- A 12-inch stainless steel rule (1) that is gradu-

ated in eighths, sixteenths, thirty-seconds, and sixty-

fourths of an inch. The rule is slotted to accept

individual tool heads. It can be used as a measuring

Figure 5-8.--Circumference rule.

5-7