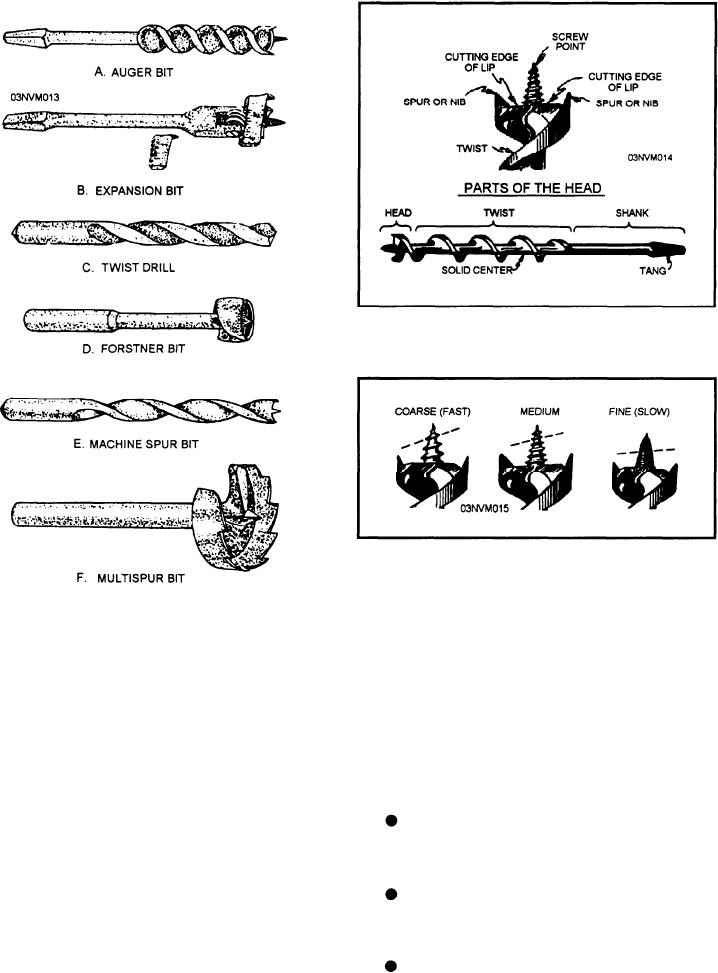

Figure 5-14.--Parts of an auger bit.

Figure 5-15.--Types of screw points.

Figure 5-13.--Drill bits.

The spurs function to score the outer edge of the

chip as the cutting lips chisel or cut the waste material

loose. The spurs and cutting lips must be sharp to

WOOD- AND METAL-BORING BITS

produce a smooth hole.

The twist of the auger bit is responsible for remov-

The wood-boring bits and drills usually found in the

ing waste material after being cut by the spurs and

HT shop are shown in figure 5-13--included are the

cutting lips. It is slightly smaller in diameter than the

auger bit, expansion bit, twist bit, machine spur bit, and

head. The twist comes in three styles--single twist with

multispur bit.

solid center, single twist, and double twist.

AUGER BIT

The single twist with solid center clears chips

more rapidly, is stronger, and is more common

The auger bit (fig. 5-13, view A) is the most com-

than the single or double twist.

mon of the wood-boring bits. It should be used with a

hand brace. It consists of three parts: the head, twist, and

The single twist has less tendency to bind in

shank, as shown in figure 5-14.

certain materials but is more fragile than the

The screw point functions to center the bit and to

single twist with solid center.

pull the bit through the stock. The three types of screw

points are coarse, medium, and fine (fig. 5-15). The

The double twist produces a clean, smooth,

coarse bit is drawn through the stock faster than a fine

accurate hole and bores slower than other

one, but there is more roughness because of the faster

twist bits. It is the most suitable of the three to

cut.

bore holes for wooden dowels.

5-10