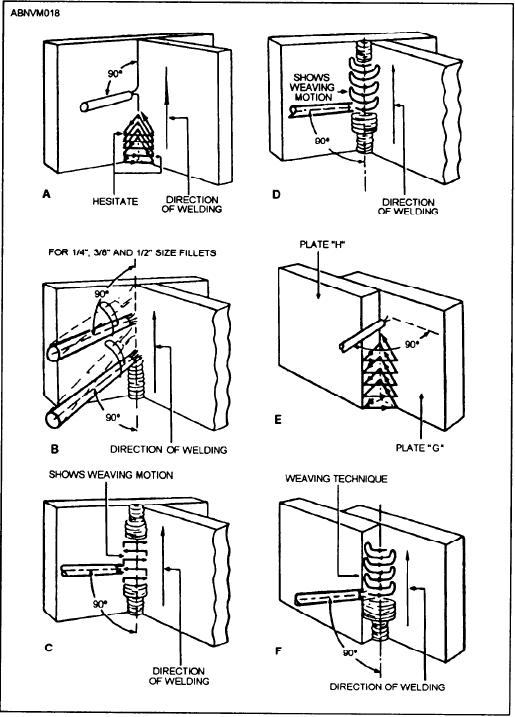

Figure 10-18.--Welding in the vertical position.

When the part being welded is free to move,

contract to its original shape and size. On the other

distortion will be caused by contractual stresses.

hand, if the bar is restrained in any way during

Distortion may be prevented by the restraint of jigs,

heating, it will not be able to expand in the direction

structural rigidity, or the support of previous

of the restraint. For example, a metal bar placed in

welding. Under such conditions, you may expect

a vise so that the jaws close against the two ends, as

residual stresses up to the yield point of the metal.

shown in figure 10-19, cannot expand towards the

If the required plastic flow exceeds the metal's

two ends. Any expansion would have to be lateral.

capacity to flow, cracking may result. When a bar

When it contracts upon cooling, however, there is

of steel is heated thoroughly and uniformly, it will

no restraint and it will contract in all directions. It

expand in all directions. If it is allowed to cool

does not return to its original shape and size

evenly, and without restraint of any kind, it will

but becomes shorter and thicker, as shown in

10-17