takes control of the arc and causes it to pull this

way and that in a wild and uncontrollable fashion.

The situation must be corrected at the first sign of

trouble or the heat will become intense and the arc

will fluctuate wildly. In a very short time, the arc

will be lost, usually with an explosive burst that

carries away the molten metal of the weld. Arc

blow causes incomplete fusion and excessive spatter.

Arc blow can often be overcome. Following is

a list of some of the methods used most often by

experienced welders:

Changing the direction of the current

flow (Remember some electrodes can only

be welded with straight or reverse polarity)

Changing ground connections

Modifying the magnetic field with metal bars

across the weld groove

Working toward the ground from any bend

in the line of weld, or by tilting the

electrode

You will have to learn by experience which of

these measures works best under various conditions.

DISTORTION

Distortion is a temporary or permanent change

in the shape or dimensions of a welded part as a

result of welding.

Expansion and contraction are the principal

causes of distortion in welding operations. During

welding, the metal is differentially heated and

subjected to drastic temperature gradients. It

becomes weaker and more easily deformed as it is

heated, and the tendency to distort is aggravated by

the degree of restraint at the weld joint.

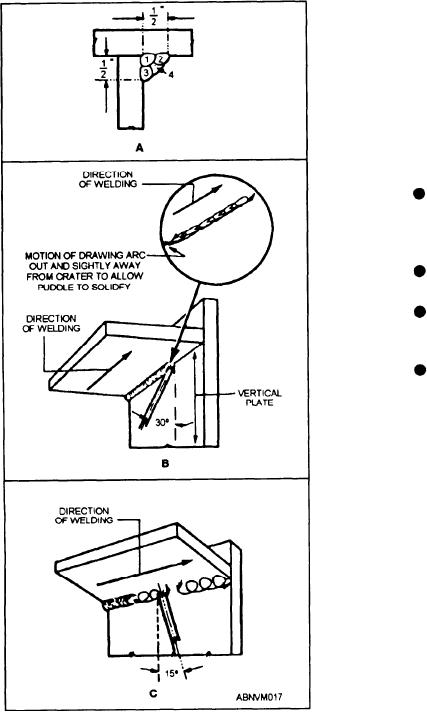

Figure 10-17.--Fillet welding of a T-joint in the overhead

During all welding operations, the weld metal

position.

and heated base metal undergo considerable

c o n t r a c t i o n when they are cooled to room

current-carrying conductor. The distortion occurs as

temperature. The surrounding cold metal offers

you approach any sudden turn in the welding; for

resistance to the shrinking of the heated area. The

example, when you are welding on an I-beam or a

weakness of the metal at elevated temperatures and

U-beam. When the field is distorted, a greater pull

the small mass of heated metal compared to the

exists on one side than on the other. When that

structure as a whole means that most of the

happens, the arc tends to blow out the side of the

adjustment must be made by the weld metal.

electrode, consuming the covering faster on that

side than on the other side. The magnetic force

10-16