valves and fittings industry. A standard identification

drain inlet and a 2-inch IPS outlet. The other has an

marking in this system usually includes the

8-inch drain inlet and a 3-inch IPS outlet.

manufacturer's name or trademark, the pressure and

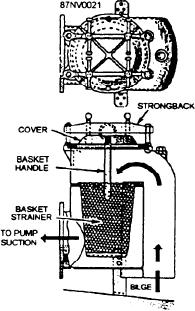

Strainers are located in all piping lines to prevent

service for which the product is intended, and the size

the passage of foreign matter. They must be installed

(in inches). When appropriate, material identification,

so that the flow will be through the strainer element.

limiting temperatures, and other identifying data are

The bilge suction strainer (fig. 15-21) is an example of

included.

a basket strainer. Some systems use duplex strainers.

The MSS standard identification markings are

The duplex strainers allow the fluid to continue flowing

generally cast, forged, stamped, or etched on the

while one of the strainers is removed for cleaning.

exterior surface of the product. However, in some

Therefore, you do not need to secure the system to clean

cases, the markings are applied to an identification plate

the strainers.

rather than to the actual surface of the product.

IDENTIFICATION OF

The service designation in the MSS system of

VALVES, FITTINGS, FLANGES,

marking usually includes a letter to indicate the type of

AND UNIONS USING THE

service and numerals to indicate the service pressure

MANUFACTURERS

rating in pounds per square inch. The letters used in

STANDARDIZATION SOCIETY

service designations are A (air), G (gas), L (liquid), O

(MSS) MARKING SYSTEM

(oil), W (water), and D-W-V (drainage, waste, and

vent).

Many valves, fittings, flanges, and unions used on

naval ships are marked with some sort of identification

When the primary service rating is for steam, and

symbol. Valves and fittings made on board repair ships

when no other service is indicated, the service

and tenders, or at naval shipyards are usually marked

designation may consist of numerals only. For

with symbols indicating the manufacturer (the ship's

example, the number 600 marked on the body of a valve

number or the insignia of the naval shipyard), the size,

would indicate that the valve is suitable for steam

the pattern number, the melt or casting number, and the

service at 600 psi. If the valve is designed for liquid at

material. They may also be marked with the date (year)

600 psi, the service designation would be 600 L.

of manufacture and with an arrow signifying the

Service designations are also used in combination; for

direction of flow.

example, the marking 3000 WOG would indicate a

product suitable for water, oil, or gas service at 3000

Many commercially manufactured valves, fittings,

psi.

flanges, and unions are identified according to a

standard marking system developed by the

In the MSS marking system, the material

Manufacturers Standardization Society (MSS) of the

designation may be either spelled out or abbreviated.

Most cast, wrought, or forged steel products are marked

with the word STEEL. Malleable iron is identified by

the abbreviation MI on newer products. On older

products, the abbreviation MAL or MALL is used.

Ductile cast iron is identified by the word DUCTILE or

by the abbreviation DI. Other symbols used for

material identification include the following:

AL . . . . . . . . . . Aluminum

B . . . . . . . . . . . Bronze

CS . . . . . . . . . . Carbon steel

CI . . . . . . . . . . . Cast iron

HF . . . . . . . . . . Cobalt-chromium-tungsten

alloy (hard facing)

CU NI . . . . . . . . Copper-nickel alloy

NI CU . . . . . . . . Nickel-copper alloy

Figure 15-21.--Basket strainer.

15-18