the slightest drop in delivered pressure, the pressure

charge in the dome instantly forces the valve open. This

allows system fluid to pass through, thereby

maintaining the outlet pressure relatively constant.

To charge the loading chamber, back off slightly on

the dome needle valve. Connect the specially furnished

hand pump (either 300 or 600 psi), and fill the dome to

the desired outlet pressure. If the regulator is to handle

a gas, charge the dome loading chamber with this gas

via the dome needle valve and the body needle valve

(fig. 15-15). If the regulator is to handle a liquid, charge

the dome from an external source. Remove the plug on

the dome loading chamber and connect the external

source. This may be an air bottle or an air pump. Keep

the body needle valve closed while you use the dome

needle valve to adjust the dome pressure to obtain the

desired outlet pressure.

HYDRAULIC CONTROL VALVES

Hydraulic control valves are used in many

shipboard systems. On some ships, they are installed in

the sections of firemain that supply water to the

magazine sprinkling systems. This type of valve may

be operated from one or more remote control stations

by a hydraulic control system.

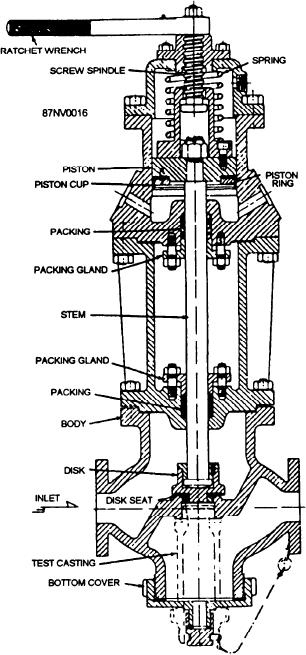

The hydraulic control valve shown in figure 15-16

is a piston-operated globe valve. It is normally held in

the closed position by both a spring force and by the

firemain pressure acting against the disk. When

hydraulic pressure is admitted to the underside of the

piston, a force is created that overcomes both the spring

tension and the firemain pressure, thereby causing the

valve to open.

Figure 15-16.--Hydraulic control valve.

When hydraulic pressure is released from under the

piston, the spring acts to force the hydraulic fluid out of

the cylinder and back to the remote control station, thus

can be removed so that you can check the valve for

closing the valve.

leakage.

A ratchet lever is fitted to the valve to allow the

emergency opening of the valve by hand. After the

TRAPS AND STRAINERS

valve has been opened by hand, you should first restore

Traps are used to remove various undesirable

the stem to its normal CLOSED position with the

materials from piping systems. In air lines, a trap is

ratchet lever. Then line up the hydraulic system from a

installed to remove the water that is usually present. In

remote control station so that the hydraulic fluid in the

steam lines, traps are installed to remove condensate.

valve cylinder can return to the storage tank at the

Some types of steam traps are suitable for low-pressure

control station. The full force of the closing spring then

use, while others are suitable for high-pressure use.

acts to seat the disk, thereby closing the valve.

However, any steam trap will consist of a valve and

The valve shown in figure 15-16 is equipped with

some device or arrangement that will cause the valve to

a test casting in the body of the valve. The bottom cover

open and close, as necessary to drain the condensate

from the lines without allowing steam to escape. The

15-15