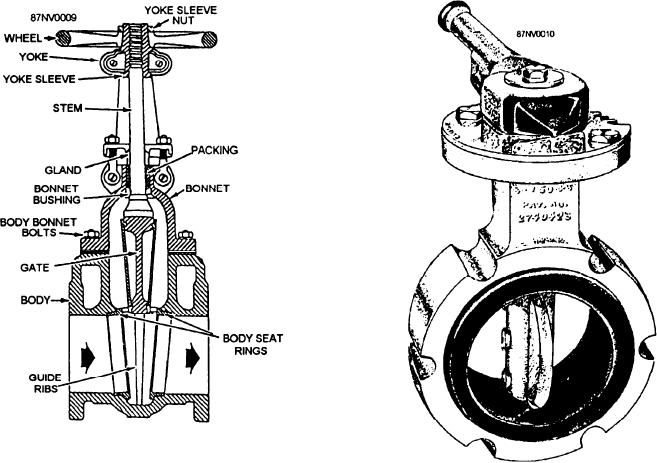

Figure 15-9.--Cross-sectional view of a gate stop valve rising

stem.

Figure 15-10.--Butterfly-type valve.

usually have a pointer or a gauge to indicate whether

the valve is in the open or closed position. Some gauge

To close the valve, turn the handle a quarter of a

valves have rising stems. In these valves, both the gate

turn to rotate the disk 90. The resilient seat exerts

and stem will move upward when the valve is opened.

positive pressure against the disk, which assures a tight

In some rising stem valves, the stem will project above

shutoff.

the handwheel when the valve is opened.

You will find that butterfly valves are easy to

BUTTERFLY VALVES

maintain. The resilient seat is held in place by

mechanical means. Therefore, neither bonding nor

The butterfly-type valve (fig. 15-10) in certain

cementing is necessary. Since the resilient seat is

applications has some advantages over gate and globe

replaceable, the valve seat will not require any lapping,

valves. The butterfly valve is lightweight, takes up less

grinding, or machine work.

space than a gate valve or globe valve, is easy to

Butterfly valves serve a variety of requirements.

overhaul, and can be opened or closed quickly.

These valves are now being used in freshwater,

The design and construction of butterfly valves may

saltwater, JP-5 fuel, Navy special fuel oil, diesel oil, and

vary, but a butterfly-type disk and some means of

lubricating oil systems.

sealing are common to all butterfly valves.

CHECK VALVES

The butterfly valve shown in figure 15-10 consists

of a body, a resilient seat, a butterfly-type disk, a stem,

Check valves permit liquids to flow through a line

packing, a notched positioning plate, and a handle. The

in one direction only. For example, they are used in

resilient seat is under compression when it is mounted

drain lines where it is important that there is no

in the valve body. The compression causes a seal to

backflow. Considerable care must be taken to see that

form around the edge of the disk and both upper and

valves are properly installed. Most of them will have

lower points where the stem passes through the seat.

an arrow, or the word INLET, cast on the valve body to

Packing is provided to form a positive seal around the

indicate direction of flow. If not, you will have to check

stem if the seal formed by the scat is damaged.

15-11