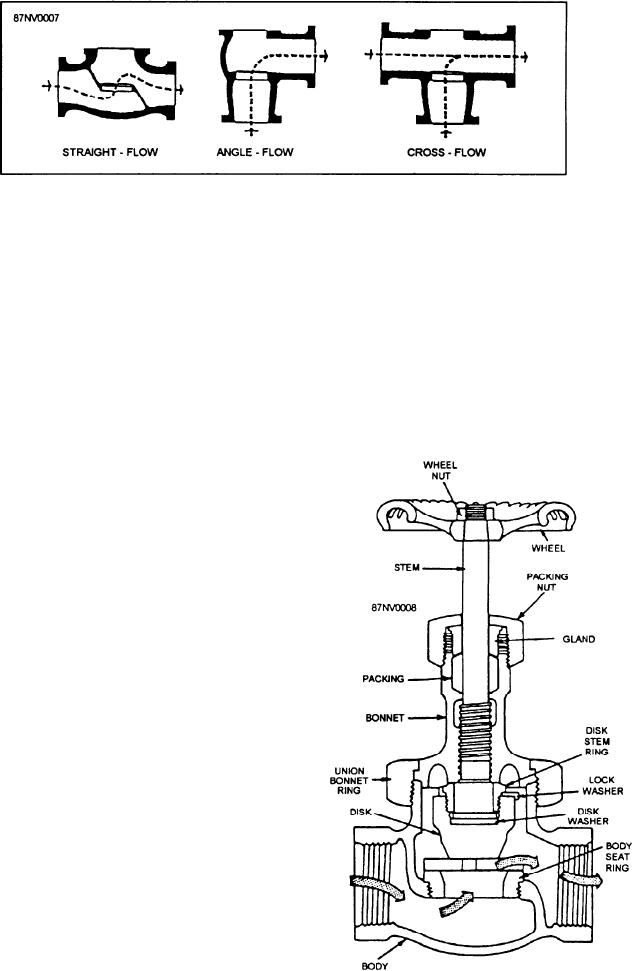

Figure 15-7.--Types of globe valve bodies.

Globe valve inlet and outlet openings are arranged

valve. Since regulating the flow of liquid would be

in several ways to satisfy different requirements of flow.

difficult and could cause extensive damage to the valve,

Figure 15-7 shows three common types of globe valve

the gate valve is not to be used as a throttling valve.

bodies. In the straight type, the fluid inlet and outlet

The gate is connected to the valve stem. Turning

openings are in line with each other. In the angle type,

the handwheel will raise or lower the valve gate. Some

the inlet and outlet openings are at an angle to each

gate valves have nonrising stems. On these, the stem is

other. An angle-type globe valve is commonly used

threaded on the lower end and the gate is threaded on

where a stop valve is needed at a 90 turn in a line. The

the inside. Therefore, the gate will travel up the stem

cross-type globe valve has three openings rather than

when the valve is being opened. This type of valve will

two; it is frequently used in connection with bypass

lines.

Globe valves are commonly used in steam, air, oil,

and water lines. On many ships, you will find surface

blow valves, bottom blow valves, boiler stops, feed stop

valves, and many guarding valves and line cutout

suction side of many fireroom pumps, as recirculating

valves in the fuel oil system, and as throttle valves on

most fireroom auxiliary machinery.

A cutaway view of a globe stop valve is shown in

figure 15-8.

GATE VALVES

Gate valves are used in systems where a straight

flow with the least amount of restriction is needed.

Figure 15-9 is a cross-sectional view of a gate valve.

You will find that most of the firemain cutout valves are

gate valves. These valves are also used in steam lines,

water lines, and fuel oil lines.

The part of a gate valve that serves the same purpose

as the disk in a globe valve is known as the gate. The

gate is normally wedge-shaped. However, some are

uniform in thickness throughout. When the gate is wide

open, the opening through the valve is equal to the size

of the piping in which the valve is installed. Therefore,

there is very little resistance in the flow of the liquid and

also very little pressure reduction caused by the gate

Figure 15-8.--Cutaway view of a globe stop valve.

15-10