valve looks very much like a lift-check valve.

However, the valve stem is long enough so that when it

is screwed all the way down it holds the disk firmly

against the seat, thereby preventing the flow of any

fluid. In this position, the valve acts as a stop valve.

When the stem is raised, the disk can then be opened by

pressure on the inlet side. In this position, the valve acts

as a check valve and allows the flow of fluid in one

direction only. The amount of fluid allowed to pass

through is regulated by the opening. The opening is

adjusted by the stem.

PRESSURE-REDUCING VALVES

Pressure-reducing valves are automatic valves that

are used to provide a steady pressure lower than that of

the supply pressure. Pressure-reducing valves can be

set for any desired discharge pressure that is within the

limits of the design.

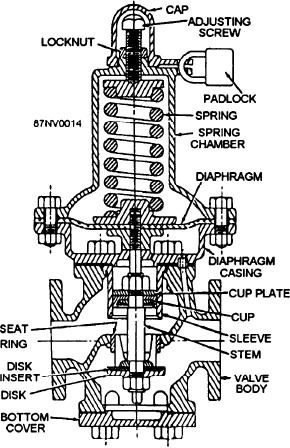

There are several types of reducing valves in the

Navy. However, you will be working mostly with those

in the flushing system. These will normally be

single-seated, direct-acting, and spring-loaded, as

shown in figure 15-14. Water passing through this

Figure 15-14.--Spring-loaded, diaphragm-type

valve is controlled by means of a pressure difference on

pressure-reducing valve.

both sides of the diaphragm. The diaphragm is secured

to the stem. Reduced water pressure from the valve

outlet is then led through an internal passage to a

The amount of pressure applied by the spring to the

diaphragm chamber that is located below the

top of the diaphragm can be adjusted by turning an

diaphragm. An adjusting spring acts on the upper side

adjusting screw. Turning the adjusting screw clockwise

of the diaphragm. A leather cup washer or a neoprene

will increase the pressure applied by the spring to the

O-ring makes the water seal between the valve inlet and

top of the diaphragm, which in turn opens the valve.

the diaphragm chamber. This seal is located halfway

Turning the adjusting screw counterclockwise will

down the valve stem.

decrease the amount of spring pressure on top of the

The amount of water pressure applied to the

diaphragm, which in turn decreases the amount of

underside of the diaphragm varies according to the

discharge.

discharge pressure. When the discharge pressure is

The opening and closing of the valve will continue

greater than the spring pressure, the diaphragm is forced

as long as the discharge pressure fluctuates. For

up. Since this is an upward-seating valve, the upward

example, when a water closet is flushed, the pressure

movement of the stem tends to close the valve or at least

drops in the supply line. This line is on the discharge

to decrease the amount of discharge. When the

side of the pressure-reducing valve. Therefore, the

discharge pressure is less than that of the spring

diaphragm will move down and open the valve. As the

pressure, the diaphragm and the valve stem are forced

flushometer closes, the pressure builds up again and

down, opening the valve wider and increasing the

closes the reducing valve.

amount of discharge. When the discharge pressure is

equal to the spring pressure, the valve stem will remain

PNEUMATIC-PRESSURE-CONTROLLED

stationary and the flow of water through the valve is not

REDUCING VALVES

changed.

There

are

two

types

of

the

pneumatic-pressure-controlled (or gas-loaded)

reducing valve. One type regulates low-temperature

15-13