Hot Bending

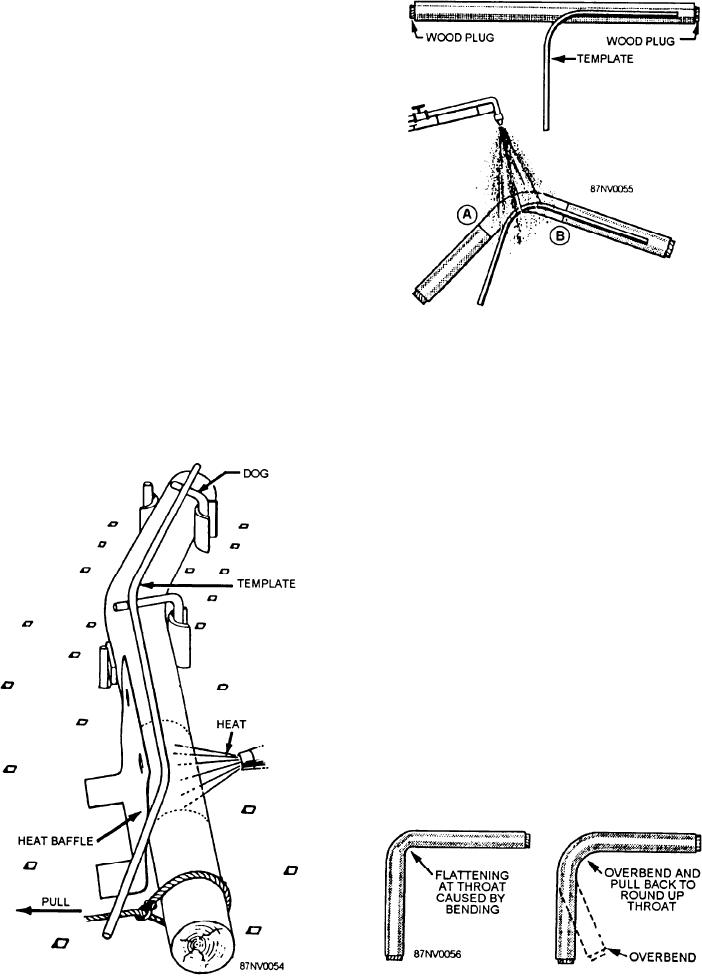

For hot bends, the bending slab (fig. 16-15) will

probably serve you best. This slab requires little

maintenance beyond a light coating of machine oil to

keep rust under control. As a preliminary step in hot

bending, pack the pipe with dry sand. Drive a tapered

wooden plug into one end of the pipe (as shown in fig.

16-16). Place the pipe in a vertical position with the

plugged end down. Then fill it with dry sand, leaving

just enough space at the upper end to take a second plug.

This will help to prevent the heel or outside of the bend

from flattening. If flattening occurs, it will reduce the

cross-sectional area of the pipe, and restrict the flow of

fluid through the system. Ensure that the sand is tightly

packed. This is done by tapping the pipe continually

with a wooden or rawhide mallet during the filling

operation. A good rule of thumb is to tap 1 hour for each

Figure 16-16.--Heating and bending pipe to conform to the

wire template.

inch of pipe diameter. The second plug is identical with

the first, except that a small vent hole is drilled through

its length. This vent permits the escape of any gases

it is heated. No matter how dry the sand may appear,

(mostly steam) that may form in the packed pipe when

there is always a possibility that some moisture is

present. This moisture will form steam, which will

expand and build up pressure in the heated pipe. If you

do not provide a vent, one of the plugs will blow out

before you can get the pipe bent.

Once you have packed the pipe with sand, mark the

bend area of the pipe with chalk or soapstone. Then heat

the pipe to an even red heat along the distance indicated

from A to B in figure 16-16. Apply heat to the bend area

first on the outside of the bend and then on the inside.

When an even heat has been obtained, bend the pipe to

conform to the centerline template. The template is also

used to mark the bend area on the pipe. When bending

steel and some other piping materials, you can control

wrinkles and flat spots by first overbending the pipe

slightly, and then pulling the end back as shown in

figure 16-17.

Figure 16-15.--Bending on a slab.

Figure 16-17.--Overbending to prevent flattening of pipe.

16-15