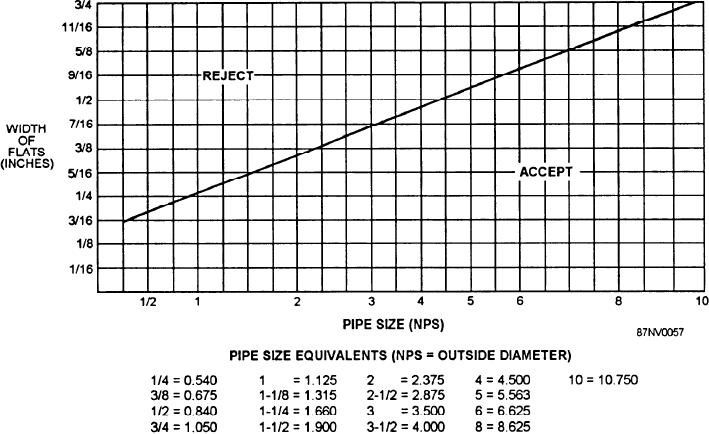

Figure 16-18.--Flatness limits graph.

rejectable. If any pipe bend is rejected for any of the

Threaded Joints

previously mentioned reasons, the pipe should be

Pipe threading is a precise machining operation.

discarded and a new section of pipe bent.

Perfect threads are possible only if the threading dies

are in good condition and properly used. Even with a

perfectly cut thread, you will not get a sufficiently tight

ASSEMBLY AND DISASSEMBLY

joint unless every step is done properly.

OF PIPING

Sometimes a leaking threaded joint can be

tightened with a reasonable amount of pull-up. If it

A great many joints are used in shipboard piping

cannot, you will have to take the joint apart, clean it,

systems. When standard fittings are used, such as

correct any bad thread conditions, recoat it with a

couplings, elbows, and T-joints, threads must be cut on

suitable thread compound, and then reassemble it.

pipes and tubing. Pipe threads cause frequent failures

When you do this, be careful to avoid new damage to

and it is often difficult to remove threaded joints. For

the threads.

this reason, welded or brazed connections fitted with

When you cut the pipe to the required length, there

flanges or unions are used whenever possible. However,

you will find threaded fittings used in flexible piping,

will be a burr on the inside. This will be true whether

in low-pressure systems, and with pipe of 2 inches IPS

you use a cutting torch, a saw, or a pipe cutter. You will

or less. Actually, a joint capable of withstanding 1000

have to remove this burr with a file or a pipe reamer.

psi can be made if perfect threads are cut and if the joint

(For more information on threading and reaming pipe,

is properly assembled.

refer to chapter 5 of this manual.)

16-17