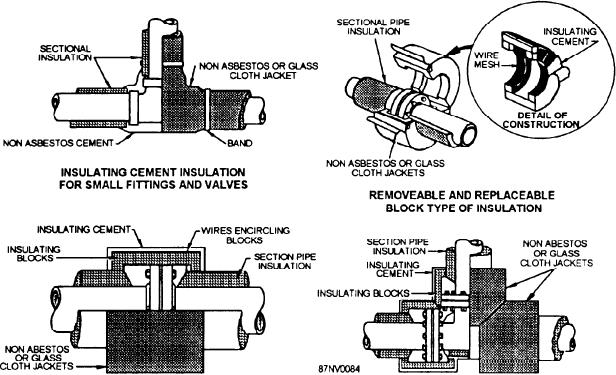

Figure 16-45.--Permanent-type insulation of pipe fittings, flanges, and valves.

Covers shouild fit perfectly and should project over

1. Covers may bc similar to the flexible fiberglass

adjacent permanent insulation.

type described for piping components.

Any one of the following methods of fabrication is

2. Covers should be made in sections formed of

acceptable for piping components:

insulating block and held together with wire and

adhesive cement. These sections should be covered

1. Covers may be made in two halves out of

with a 1/2-inch thickness of finishing cement, and

thermal insulating felt enclosed with 0.008-inch

diameter knitted wire mesh on the inside and end

lagged. Lace with hooks, rings, washers, and wire, or

surfaces. The outside of the covers will have a fibrous

brass snap fasteners to secure the covers.

glass fabric conforming to MIL-C-20079, class 9.

Observe the following general precautions when

Each half cover may be sewn and quilted with

you apply and maintain insulation:

polyetrafluoroethylene (PTFE) coated fibrous glass

1. Fill and seal all air pockets and cracks. Failure

yarn or thread. The covers may also be fastened with

to do this will cause large losses by conduction and by

stainless-steel staples to provide uniform thickness,

2. Covers exposed to temperatures of 450F and

2. Seal the ends of the insulation and taper off to a

above must have a 0.008-inch diameter knitted wire

smooth, airtight joint. Use sheet metal lagging at joint

mesh on the inside surface and on the ends. Fibrous

ends or other points where insulation is liable to

glass cloth conforming to MIL-C-20079, class 9, must

damage. Cuff flanges and joints with 6-inch lagging.

be used on all outside surfaces. Covers for use at

3. Fibrous glass cloth covering fitted over

temperatures of 850F and above must have a filling

insulation should be tight and smooth. It may be sewed

consisting of fibrous glass felt, MIL-I-23128. The

with yarn or may be cemented on.

knitted wire mesh must be made of 304 annealed

stainless steel.

4. Keep moisture out of all insulation work.

Moisture is an enemy of heat insulation. Any dampness

Either of the following methods of fabrication is

acceptable for removable and replaceable covers for

machinery and equipment:

materials.

16-40