1. Remove all foreign material such as paint,

THREAD LEAKS

All leaking threaded joints that cannot be tightened

of pipe or tubing for at least 6 inches on each side of the

with a reasonable amount of pull-up should be taken

repair area; it is not necessary to polish the pipe. The

apart, cleaned, and examined to remove bad thread

pipe or tubing should be clean, dry, and free of solvents

conditions. Recoat with a compound suitable for the

and flammable vapors.

intended service, and carefully reassemble to avoid any

2. Pipe or tubing requiring repair may show cracks

other thread damage. Poorly cut threads are a constant

or other defects indicative of incipient failure. In the

source of trouble with threaded joints. Therefore, it is

area to be repaired where such defects are not obvious,

essential that thread cutters receive proper use and care.

liquid-penetrant test the area before pressurizing to

Various thread leak causes and corrective measures

ensure that undetected defects are not present.

to be taken are listed in table 16-6.

For additional information on the characteristics,

special requirements and procedures, and the types and

PREPARATION OF PIPES FOR REPAIR

frequency of tests and inspections to be conducted on

specific piping systems, refer to NSTM, chapter 505. For

more information on the repair of hydraulic systems,

Prepare pipes requiring repair according to the

consult NSTM, chapter 556.

procedures described in the following paragraphs:

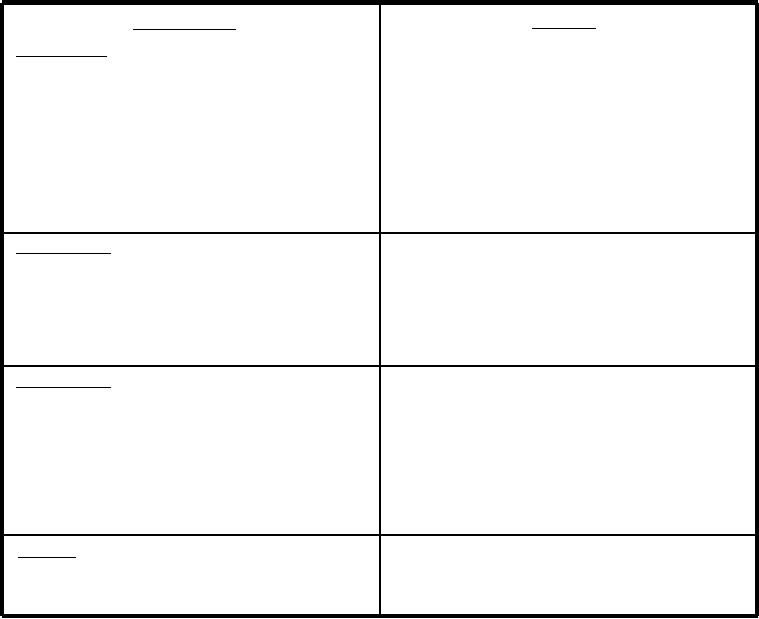

Table 16-6.--Thread Leak Causes and Corrective Measures

Correction

Cause of Trouble

Rough Threads:

Sharpen

Dull chasers

Use plenty of good oil

Insufficient lubrication

Grind properly

Excessive or insufficient lead cutting

Grind to correct angle

Grind out entire tooth

Broken tooth in chaser leader

Clean slots, set chasers to true cutting circle, grind

Chaser not set to form true cutting circle

chasers, if necessary, to a uniform length

Shaved Threads:

Regrind lead

Improper lead of chaser

Keep slots clean

Chasers not tracking properly

Correct setting

Chasers not set in correct rotation

Repair carriage

Carriage travel retarded (machine only)

Wavy Threads:

Center die or chasers; get new die head

Die or chasers not true (manual only); loose chasers

(machine)

Tighten with wrench; get new die head

Thumb screws not tight (manual only); worn cam

in head (machine)

Get new die stock

Keep slots clean

Cuttings or dirt in chaser slots (manual only)

Shoulders:

Recut square and rethread

Pipe ends not square (manual only)

Die and chuck not aligned (machine)

Check and realign

16-45