that after a little while, you will form a mental image of

the individual spark. After you can fix the spark image

in mind, you are ready to examine the whole spark

picture.

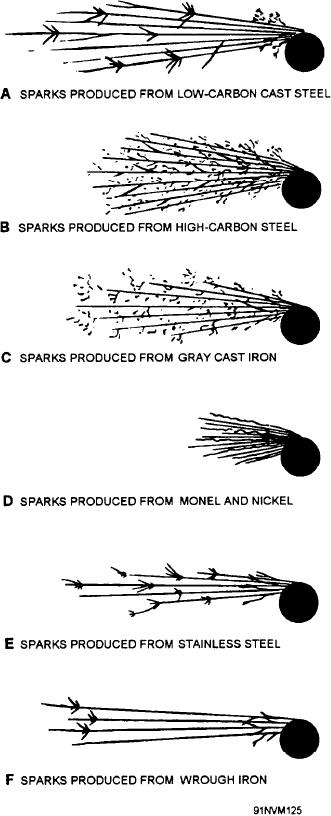

Notice that the spark stream is long (about 70 inches

normally) in low-carbon steel, and that the volume is

moderately large; while in high-carbon steel, the stream

is shorter (about 55 inches) and larger in volume. The

few sparklers that may occur at any place in low-carbon

steel are forked, while in high-carbon steel the sparklers

are small and repeating, and some of the shafts may be

forked. Both will produce a white spark stream.

White cast iron produces a spark stream approxi-

mately 20 inches in length (see fig. 6-11). The volume

of sparks is small with many small and repeating spar-

klers. The color of the spark stream close to the wheel

is red, while the outer end of the stream is straw colored.

Gray cast iron produces a stream of sparks about 25

inches in length. It is small in volume with fewer

sparklers than white cast iron. The sparklers are small

and repeating. Part of the stream near the grinding wheel

is red, and the outer end of the stream is straw colored.

The malleable iron spark test will produce a spark

stream about 30 inches in length. It is of a moderate

volume with many small, repeating sparklers toward the

end of the stream. The entire stream is straw colored.

The wrought iron spark test produces a spark stream

about 65 inches in length. The stream is of large volume

with few sparklers. The sparklers show up toward the

end of the stream and are forked. The stream next to the

grinding wheel is straw colored, while the outer end of

the stream is a bright red.

Stainless steel produces a spark stream approxi-

mately 50 inches in length, of moderate volume, with

few sparklers. The sparklers are forked. The stream next

to the wheel is straw colored. The sparks form wavy

streaks with no sparklers.

Monel metal forms a spark stream almost identical

to that of nickel and must be identified by other means.

Copper, brass, bronze, and lead form no sparks on the

Figure 6-11.--spark pictures formed by common metals.

grinding wheel, but they are easily identified by other

means, such as color, appearance, and chip tests.

You will find the spark tests easy and convenient to

have similar spark patterns. It is the practice in many

make. They require no special equipment and are adapt-

metal shops to maintain a cabinet of commonly used

able to most any situation. Here again, experience is the

metals, positively identified as to grade, for com-

best teacher.

parison with unknown samples.

It is good practice to compare the sparks of an

Proper lighting conditions are essential for good

unknown metal with those of a known metal. This

spark testing practice. Testing should not be done in

permits an additional check on the tester's conclusion

strong direct lighting. A dark background for the spark

and also can distinguish between different metals that

6-16