may have been done to the metal affecting its

pattern should be used. Heavy drafts of air against the

properties. The metal may not melt and fuse readily.

spark pattern should be avoided as the air can change

the tail sparks. Such a change will lead to incorrect

The final weld may be unsatisfactory. The usual cause

identification.

of this condition is that there are impurities imbedded

in the metal. The impurities are usually slag and roller

dirt or excessive sulphur and phosphorus. For these

Oxyacetylene Torch Test

reasons, a welder should subject steel to the torch test.

Metals may sometimes be identified by their

Even if you know the physical composition and

characteristic reactions to being heated with an

oxyacetylene welding torch. Identifying factors

know whether the metal has good welding properties.

include the rate of melting, the appearance of the

For example, some cold rolled sheet steels may show

molten slag, and the color changes (if any) that occur

very good physical and chemical properties. However,

during the heating. Table 6-4 indicates the reactions

during some part of the manufacturing process,

impurities may have been added to it or certain work

of various metals to the torch test.

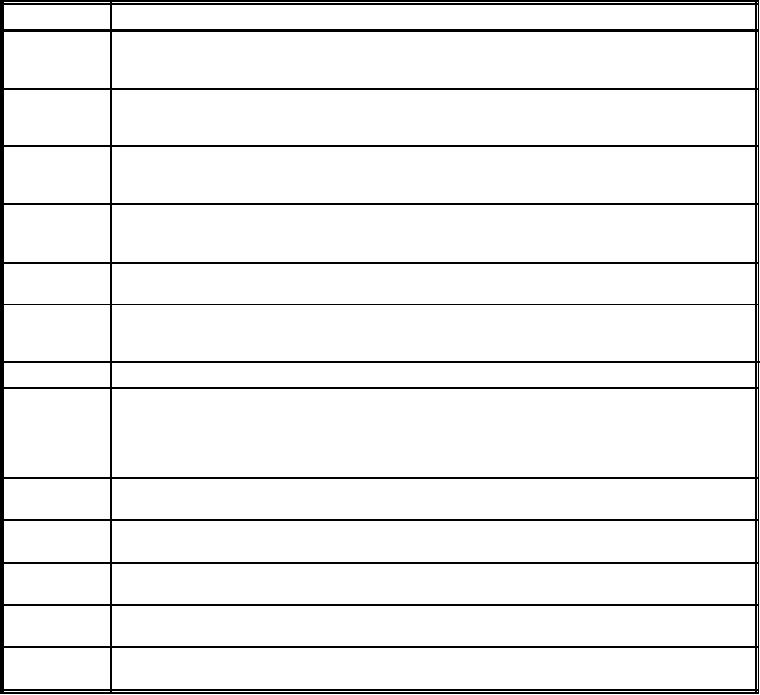

Table 6-4.--Identification of Metals by Oxyacetylene Torch Test

Reactions When Heated By Oxyacetylene Torch

Metals

White cast iron

Metal becomes dull red before melting. Melts at moderate rate. A medium tough film of slag develops. Molten

metal is watery, reddish white in color, and does not show sparks. When flame is removed, depression in

surface of metal under flame disappears.

Gray cast iron

Puddle of molten metal is quiet, rather watery, but with heavy, tough film forming on surface. When torch

flame is raised, depression in surface of metal disappears instantly. Molten puddle takes time to solidify, and

gives off no sparks.

Malleable iron

Metal becomes bright red before melting: melts at moderate rate. A medium tough film of slag develops, but

can be broken up. Molten puddle is straw colored, watery, and leaves blowholes when it boils. Center of

puddle does not give off sparks, but the bright outside portion does.

Wrought iron

Metal becomes bright red before it melts. Melting occurs quietly and rapidly, without sparking. There is a

characteristic slag coating, greasy or oily in appearance, with white lines. The straw-colored molten puddle

is not viscous, is usually quiet but may have a tendency to spark; is easily broken up.

Low-carbon and Melts quickly under the torch, becoming bright red before it melts. Molten puddle is liquid, straw colored,

cast steel

gives off sparks when melted, and solidifies almost instantly. Slag is similar to the molten metal and is quiet.

High-carbon

Metal becomes bright red before melting, melts rapidly. Melting surface has cellular appearance, and is

steel

brighter than molten metal of low-carbon steel; sparks more freely, and sparks are whiter. Slag is similar to

the molten metal and is quiet.

Stainless steels

Copper

Metal has high heat conductivity; therefore, larger flame is required to produce fusion than would be required

for same size piece of steel. Copper color may become intense before metal melts; metal melts slowly, and

may turn black and then red. There is little slag. Molten puddle shows mirror like surface directly under flame,

and tends to bubble. Copper that contains small amounts of other metals melts more easily, solidifies more

slowly, than pure copper.

These metals melt very rapidly, becoming noticeably red before melting. True brass gives off white fumes

Brass and

Bronze

when melting. Bronze flows very freely when melting, and may fume slightly.

Aluminum and

Melting is very rapid, with no apparent change in color of metal. Molten puddle is same color as unheated

aluminum alloys metal and is fluid; stiff black scum forms on surface, tends to mix with the metal, and is difficult to remove.

Monel

Melts more slowly than steel, becoming red before melting. Slag is gray scum, quiet and hard to break up.

Under the scum, molten puddle is fluid and quiet.

Nickel

Melts slowly (about like Monel), becoming red before melting. Slag is gray scum, quiet and hard to break up.

Under the scum, molten puddle is fluid and quiet.

Lead

Melts at very low temperature, with no apparent change in color. Molten metal is white and fluid under a thin

coating of dull gray slag. At higher temperature, puddle boils and gives off poisonous fumes.

6-17