Chip Test

The actual test consists of melting a puddle in the

steel. If the metal is thin, the puddle penetrates through

Another test that must be accompanied by

the thickness of the steel until a hole is formed. This

considerable experience is the chip test. To make a

puddling should be done with a neutral flame, held at

chip test, use a sharp cold chisel to remove a small

the proper distance from the metal. The puddle should

amount of metal from a sample. The ease with which

not spark excessively or boil. The puddle should be

the chipping can be done gives some indication of the

fluid and should possess good surface tension. The

kind of metal with which you are working. The size,

appearance on the edge of the puddle or hole indicates

form, and color of the chips and the appearance of the

the weldability of the steel. If the metal that was

edges (whether smooth or sawtoothed) give further

melted has an even, shiny appearance upon

clues.

solidification, the metal is generally considered as

having good welding properties. However, if the

In this test, the cutting action of the chisel

molten metal surface is dull or has a colored surface,

indicates the structure and heat treatment of the metal.

the steel is unsatisfactory for welding. The steel is also

Cast iron, for example, when being chip-tested, breaks

considered unsatisfactory for welding if the surface is

off in small particles, whereas a mild steel chip tends

rough, perhaps even broken up into small pits or

to curl and cling to the original piece. Higher-carbon,

porous spots.

heat-treated steels cannot be tested this way because

of hardness. A rough test between mild carbon steel

This test is accurate enough for most welding. The

and chrome-moly steel may be indicated by the

test is very easily applied with the equipment on the

relative hardness of the metals while being

job. The test determines the one thing that is

hacksawed.

fundamentally necessary in any welding job, that is,

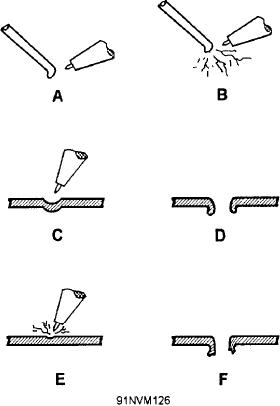

the weldability of the metal. Figure 6-12 shows how

You will not be able to identify metals by the chip

this test is conducted. While performing the

test method until you have had considerable

weldability test of the metal, it is important to note the

experience. You should practice with samples of

amount of sparking emitted from the molten metal. A

known metals until you have learned how to identify

metal that emits few sparks has good welding

c a r b o n steel, carbon-molybdenum steel,

qualities.

chromium-molybdenum steel, chromium-nickel steel,

and other metals. The information given in table 6-5

will help you to recognize some of the more common

metals.

Fracture Test

The fracture test is used extensively and consists

of breaking a portion of the metal in two. If it is a repair

job, the fractured surface may be inspected. The

appearance of the surface where the metal is cracked

shows the grain structure of the metal. If the grains are

large, the metal is ductile and weak. If the grains are

small, the metal is usually strong and has better

ductility. Small grains are usually preferred. The

fracture shows the color of the metal, which is a good

means of identifying one metal from another. The test

also indicates the type of metal by the ease with which

it may be fractured.

Color Test

The color test separates two main divisions of

metals. The irons and steels are indicated by their

Figure 6-12.--Torch flame test: (A) Good quality filler rod. (B)

typical gray white color. Nonferrous metals come in

Poor quality filler rod. (C) and (D) Good quality base

two general color classifications of yellow and white.

metal. (E) and (F) Poor quality base metal.

6-18