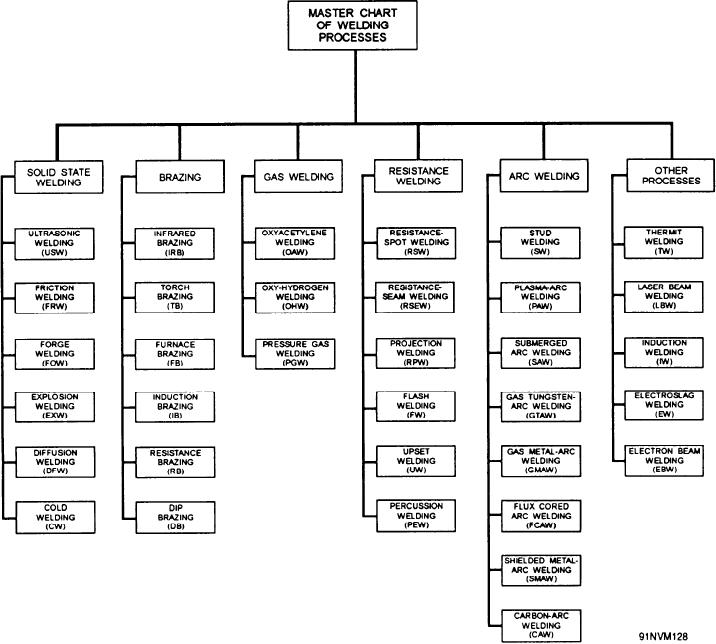

Figure 7-1.--Welding processes.

processes except brazing use temperatures high

such as acetylene or hydrogen in air or in oxygen;

enough to melt the base metals. Brazing is the

an electric arc; an electric, gas, or oil furnace; the

ONLY welding process in which the melting of the

resistance of metal to the flow of electric current; or

base metal is not necessary for coalescence. Brazing

a chemical reaction between a metal oxide and

i s similar to soldering, except that higher

finely divided aluminum. The welding processes

temperatures are used for brazing. The term

most commonly used aboard ship involve the

SOLDERING is used to describe a joining process

combustion of a fuel gas, as in oxyacetylene welding

using nonferrous filler alloys melting below 800F

and torch brazing; the use of an electric arc, as in

(427C). Soldering is NOT considered a welding

metal-arc welding; and the resistance of metal to the

process. Brazing is a welding process using

flow of electric current, as in spot welding.

nonferrous filler alloys that have a melting point

above 800F (427C) but below that of the base

The intensity of heat applied or generated at the

metal.

joint varies according to the metals being joined and

to the welding process being used. All welding

7-2