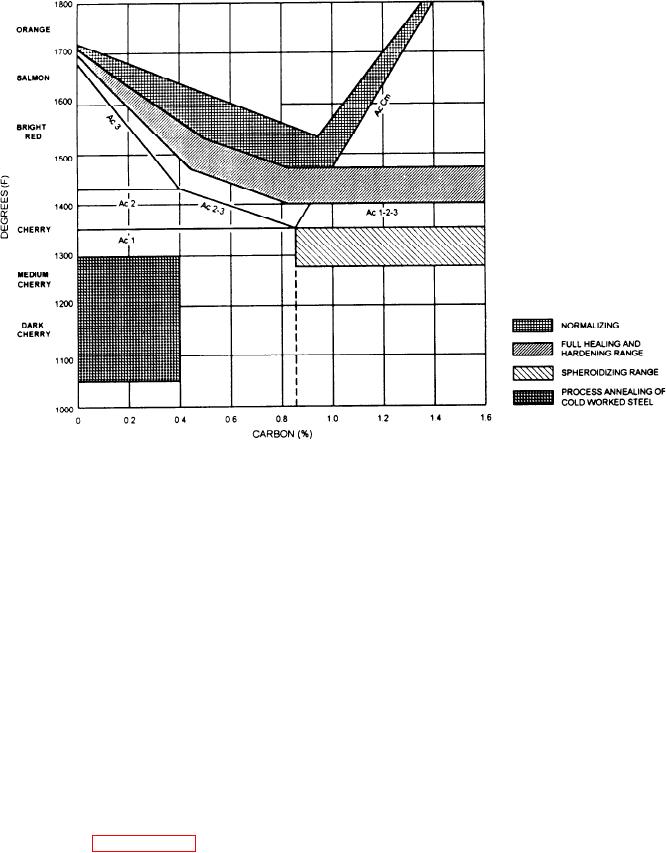

Figure 15-18.--Heat treatment temperature ranges.

twist drills, and other tools must be hardened so they

Available information indicates that the Mf of

can retain their cutting edges. surfaces of roller

high-carbon steels is actually below room temperature.

bearings, parallel blocks, and armor plate must be

Slight amounts of austenite are frequently retained in

hardened to prevent wear and penetration. Hardening is

quenched steels, especially in the higher carbon grades,

used to increase tensile strength as well as to increase

even when they are cooled to room temperature.

the material, most alloys are tempered after being

HEAT-TREATING FERROUS METALS

hardened.

The heat-treating processes most commonly used

Steels are hardened by being heated to a

for ferrous metals are hardening, tempering, annealing,

temperature just above the upper transformation

normalizing, spheroidizing, and case hardening.

temperature, soaked long enough to ensure a

Annealing is the only one of these processes that is also

completely austenitic structure, and then cooled

used for nonferrous metals. Some nonferrous metals

rapidly. This result is either fine-grained pearlite,

(including some aluminum alloys and some magnesium

bainite, or martensite. If maximum hardness is to be

alloys) can be hardened by a process generally referred

developed, the austenite must be transformed to

martensite. Martensite is extremely hard and strong,

hardening is discussed in the section of this chapter on

has great resistance, and has practically no machin-

ability.

treatment temperature ranges. You should refer to this

Carbon steels are usually quenched in brine or water

figure as you study the following information on

hardening, normalizing, and spheroidizing temper-

to ensure rapid cooling. The production of martensite

throughout a plain-carbon steel is extremely difficult,

atures.

requiring that the steel be cooled to below 1,000F in

less than 1 second and that the remainder of the cooling

HARDENING

be quite rapid. If more than 1 second is taken for the first

part of the cooling (to below 1,000F), some of the

Many tools and pieces of equipment must be

austenite will transform into fine pearlite. Pearlite varies

hardened before they are used. Cutting tools, chisels,

15-20