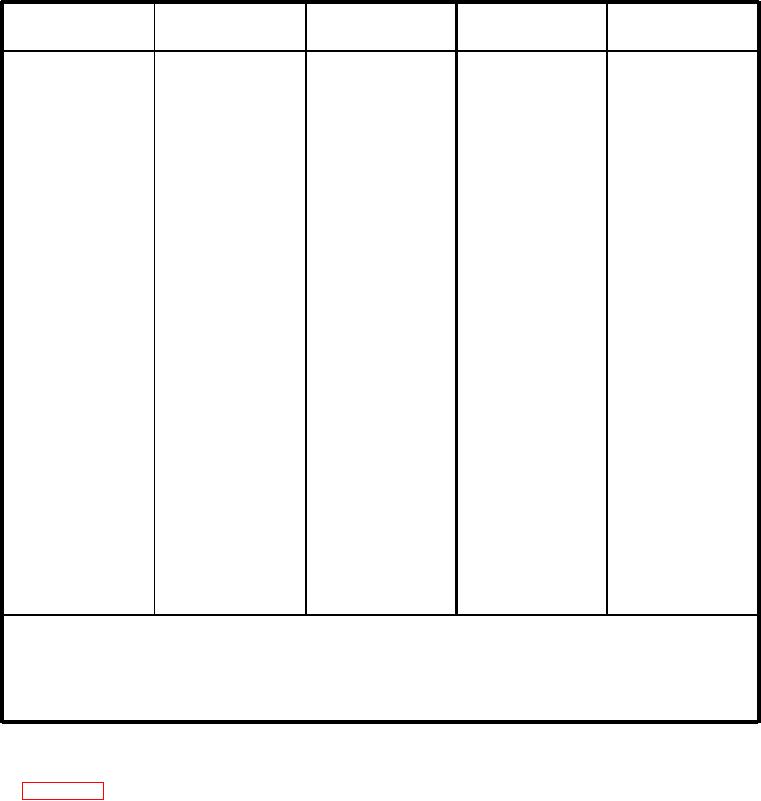

Table 15-4.--Heat-Treating Temperatures and Quenching Medium for Standard SAE Steels

HARDENING

TEMPERING

NORMALIZING

TEMP. (F)

TEMP. (F)

QUENCH

TEMP. (F)

SAE NO.

1020

1650-1700

1600-1650

water

200

1030

1650-1700

1600-1650

water

200

1040

1600-1650

1500-1550

water

200

1050

1600-1650

1500-1550

water

200*

1550-1600

1450-1550

1060

water or oil

200*#

1070

1550-1600

1450-1550

water or oil

200*#

1080

1550-1600

1450-1500

water or oil

200*#

1090

1550-1600

1450-1500

water or oil

200*#

1345

1600-1700

1450-1500

oil

200*

2345

1600-1700

1450-1500

oil

2008

3140

1600-1650

1455-1550

oil

200"

4130

1600-1650

1550-1600

200*

water

4140

1600-1650

1525-1575

oil

200*

4340

1600-1650

1475-1525

oil

200*

4060

1550-1600

1500-1550

oil

200*

5140

1600-1650

1500-1550

oil

200*

5210

1550-1600

1425-1475

200*

water

6150

1600-1650

1550-1600

oil

200*

8630

200*

1600-1650

1550-1600

water

8640

1525-1575

1600-1650

oil

200*

*Temper immediately after quenching. Lower temperatures will result in a harder final product.

#Use water for maximum hardness. Use oil for toughness and for intricate shapes.

Note: Temperature of water quench is 70F.

Temperature of oil quench is 120-150F.

all-around tool steel for this purpose is type 01. This

quenching medium and temperatures for the standard

steel is listed under QQT-570 and is available in the

SAE steels.

standard stock system in various shapes and sizes. Type

01 is suitable for all applications except where a

ALLOY TOOL STEELS

high-speed steel is required. It heat treats well and is

readily machinable in the spheroidized condition. Type

The number of alloy tool steels is too great to

01 stock replaces the 46S40 class C-5.

include them all in this text, so we will deal with the

Type 01 should be preheated slowly to 1,200F,

type most important to you. You, as a Machinery

then transferred to an oven at l,450F and soaked at heat

Repairman, are concerned primarily with the manu-

facture of taps, dies, reamers, hobs, and form tools. An

for about 20 minutes per inch of cross section, and then

15-24