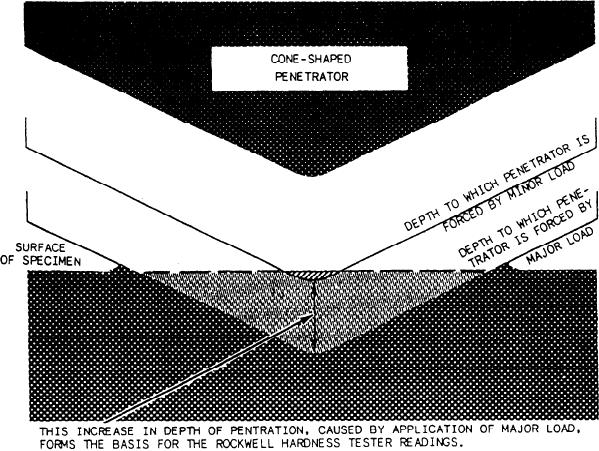

Figure 15-24.--Principle of the Rockwell hardness test.

The Rockwell superficial tester differs from the

normal Rockwell tester in the amount of load applied to

slightly.)

perform the test and in the kind of scale used to interpret

With the Rockwell tester, a deadweight, acting

the results. While the major loads on the normal tester

through a series of levers, is used to press the ball or

are 100 and 150 kg, the major loads on the superficial

cone into the surface of the metal to be tested. Then, the

tester are 15, 30, and 45 kg. One division on the dial

depth of penetration is measured. The softer the metal

gauge of the normal tester represents a vertical

being tested, the deeper the penetration will be under a

displacement of the indenter of 0.002 millimeter (mm).

given load. The average depth of penetration on samples

One division of the dial gauge of the superficial tester

of very soft steel is only about 0.008 inch. The hardness

represents a vertical displacement of the indenter of

0.001 mm. Hardness scales for the Rockwell superficial

is indicated on a dial, calibrated in the Rockwell B and

tester are the N and T scales. The N scale is used for

the Rockwell C hardness scales. The harder the metal,

materials that, if they were thicker, would usually be

tested with the normal tester using the C scale. The T

are usually tested with the spheroconical penetrator,

scale is comparable to the B scale used with the normal

with hardness numbers being read from the Rockwell

tester. In other respects, the normal and superficial

C scale. The steel ball is used for nonferrous metals, and

Rockwell testers are much alike.

the results are read on the B scale.

Once you have prepared your sample for testing,

With most indenter-type hardness tests, the metal

refer to your testers operator manual for step-by-step

being tested must be sufficiently thick to avoid bulging

operating instructions.

or marking the opposite side. The specimen thickness

should be at least 10 times the depth of penetration. It

FILE HARDNESS TEST

is also essential that the surface of the specimen be flat

and clean. When hardness tests are necessary on thin

The simplest method of testing a material's

material, a superficial Rockwell tester should be used.

hardness is the file hardness test. This test cannot be

15-29