In carburized steel, spalling is caused by an

undesired carbide network which formes of grain

boundaries. To prevent in carburized steel, quench the

parts immediately upon removing them from the

carburized medium if the grains have not increased in

size. If there has been an increase in grain size, reheat

the metal to its critical temperature of the core and the

case. Improper use of grinding wheels and insufficient

use of coolant to keep the surface of the metal cool at

all times will also cause spalling.

BLISTERING

Special care must be taken in heat-treating wrought

aluminum alloy to prevent blistering. Blistering is

caused by overheating and, in some cases, oversoaking.

Overheated hardenable aluminum alloys are rendered

useless because the eutectic constituent has melted.

HARDNESS TEST

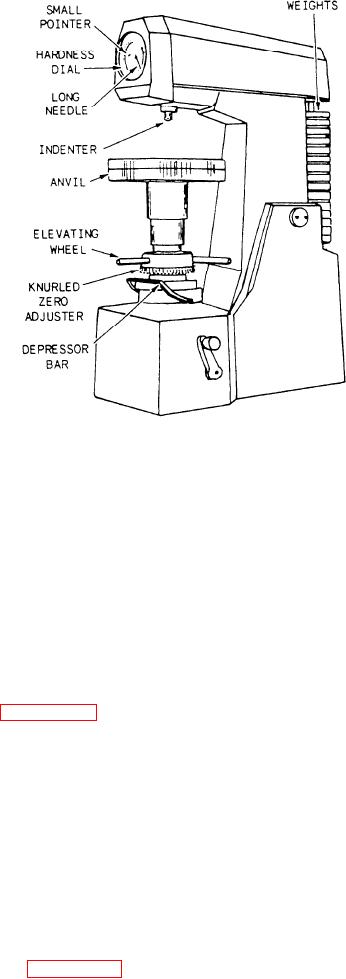

Figure 15-23.--Standard Rockwell hardness testing machine.

A number of tests are used to measure the physical

properties of metals and to determine whether a metal

meets specification requirements. Some of the more

ROCKWELL HARDNESS TEST

common tests are hardness tests, tensile strength tests,

shear strength tests, bend tests, fatigue tests, and com-

Of all the hardness tests, the Rockwell is the one

pression tests. Of primary importance to a Machinery

most frequently used. The basic principle of the

Repairman after heat-treating metal is the hardness test.

Rockwell test (like that of the Brinell, Vickers,

Eberbach, Tukron, and Monotron tests) is that a hard

Most metals possess some degree of hardness--that

material will penetrate a softer one. This test operates

is, the ability to resist penetration by another material.

on the principle of measuring the indentation, in a test

Many tests for hardness are used; the simplest is the file

piece of metal, made by a ball or cone of a specified size

hardness test, which will be discussed later in this

that is being forced against the test piece of metal with

chapter. While fair estimates of hardness can be made

specified pressure. In the Rockwell tester, shown in

by an experienced worker, more consistent quantitative

measurements are obtained with standard hardness

measuring the depression made by a hardened steel ball

testing equipment.

(indenter) or a spheroconical diamond penetrator of a

given size under a given pressure.

Hardness may be measured by many types of

instruments. The most common are the Rockwell and

With the normal Rockwell tester shown, the 120

Brinell hardness testers. Other hardness tests include the

spheroconical penetrator is used in conjunction with a

Vickers, Eberbach, Monotron, Tukon, and Scleroscope.

150-kilogram (kg) weight to make impressions in hard

metals. The hardness number obtained is designated

Since there are many tests and the hardness numbers

Rockwell C (Rc). For softer metals, the penetrator is a

derived are not equivalent, the hardness numbers must

1/16-inch steel ball used in conjunction with a 100-kg

be designated according to the test and the scale used in

weight. A hardness number obtained under these

the test. Comparison charts for the various hardness

conditions is designated Rockwell B (Rb).

numbers can be found in the current edition of the

Machinery's Handbook. Since you are more likely to

have access to a Rockwell tester than any other, we will

hardness tests. Although the conical penetrator is

shown, the principle is the same for a ball penetrator.

discuss this method.

15-28