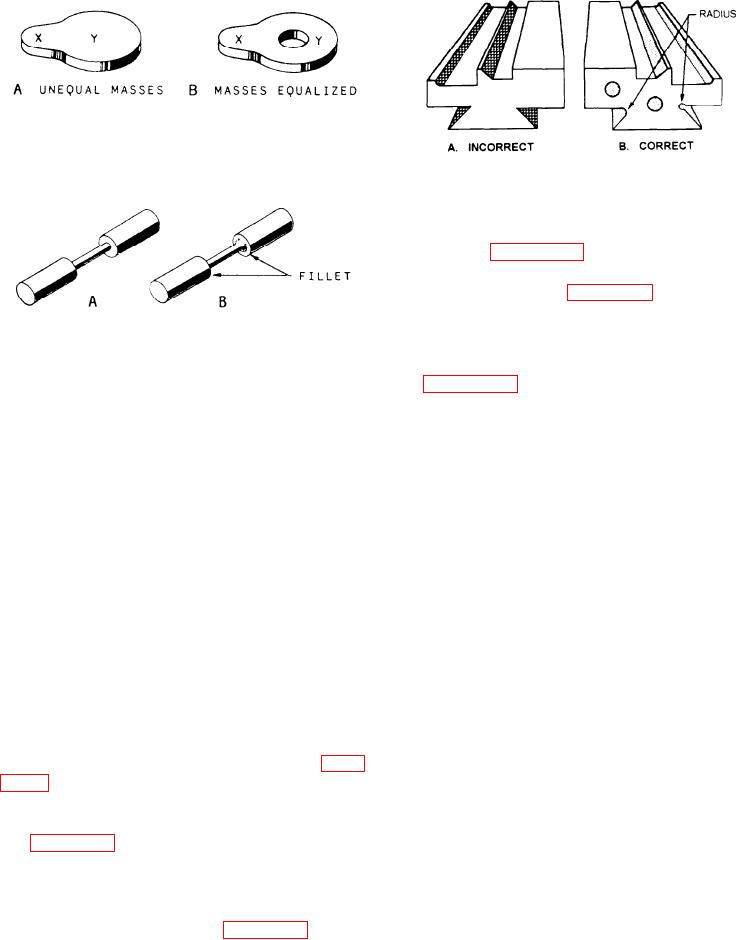

Figure 15-20.--Design of a cam. A. Unequal masses not

satisfactory for heat treatment. B. Equalized masses

satisfactory for heat treatment.

Figure 15-22.--Two designs for undercutting a form tool.

A. Poor design. B. Correct design.

necessarily have unbalanced masses, the use of a fillet

junction of the smaller and the larger masses would tend

to reduce the danger of the piece cracking from heat

B. Use of fillet design to reduce danger of cracking during

treatment.

heat treatment.

form tools. The design shown in view A does not lend

itself to heat treatment because of the combination of

with perfect uniformity, since some parts of it must

heavy and light sections and because of the sharp

always cool before others. In a well-designed piece,

corners. The design shown in view B corrects both of

however, the cooling is as uniform as possible for a

these errors. The corners have been rounded where

possible, and holes have been drilled through the two

For example, consider the cooling of a cube of steel.

heaviest sections to make the masses more nearly

The surfaces of the cube will cool evenly except at the

balanced.

edges and at the corners. At each edge there are two

surfaces that dissipate heat at the same time, and at each

In general, parts that are designed with sharp

corner there are three surfaces. Consequently, the

corners or unequal masses are extremely difficult to

corners cool more rapidly than the edges, and the edges

heat-treat. When the design cannot be improved, you

cool more rapidly than the surface areas that are not at

will have to determine the best way to heat-treat the put

the edges or corners. If the rate of cooling is extremely

to reduce the chances of cracking or distortion.

rapid, the difference in cooling rate between corners,

Even with a poorly designed part, there are two

edges, and other surface areas could be sufficient to

cause cracking.

ways in which you can usually reduce the problems of

heat-treating. First, you can select the method of cooling

Unequal masses in a single piece are likely to cause

that will be safest while still producing the required

trouble when the piece is heat-treated. View A of figure

properties in the metal. For example, flush quenching

15-20 shows a cam that might very well become

of some areas might help to solve the problem. And

distorted or cracked during heat treatment because the

second, you can shield the danger spots by packing them

mass of area X is smaller than the mass of area Y. View

with fire-resistant cloth and sheet steel or other

may be equalized, while still keeping the required shape

materials to reduce the rate of heating and the rate of

of the cam. The design shown in view B would not be

cooling in the areas that would otherwise tend to distort

as likely to distort or crack during heat treatment.

or crack. Shielding materials for steel are usually

fastened in place with soft iron wire; the wire must have

a very low carbon content so it will not become hard

design features that would make heat treatment

and brittle and fall off during the heat treatment. Holes

difficult. First, it has unequal masses; and second, it has

near an outside edge or between an edge and an interior

sharp junctions where the smaller mass joins the larger

end portions. A better design for heat treatment is shown

opening are usually packed with asbestos rope.

15-26