transformations to be completed in the normal manner,

resulting in quite different structures than those

obtained by very slow cooling of the same material.

Remember this fact about cooling-if you do not cool

a metal properly, you will not get the desired results, no

matter how carefully you heat and soak the metal. In

addition, very rapid cooling can cause internal stresses

in your material, which may lead to cracking.

In plain-carbon steel, the properties of the material

are largely determined by the form and distribution of

the ferrite and the cementite. Most heat treatment of

plain-carbon steels consists of heating the material

slightly above its transformation temperature, holding

it at this temperature until it is completely austenitic,

and then cooling it at the rate required to produce a

particular kind of structure. Thus austenite, a solid

solution of carbon and gamma iron, might be

considered the basis from which all plain-carbon steel

structures are derived.

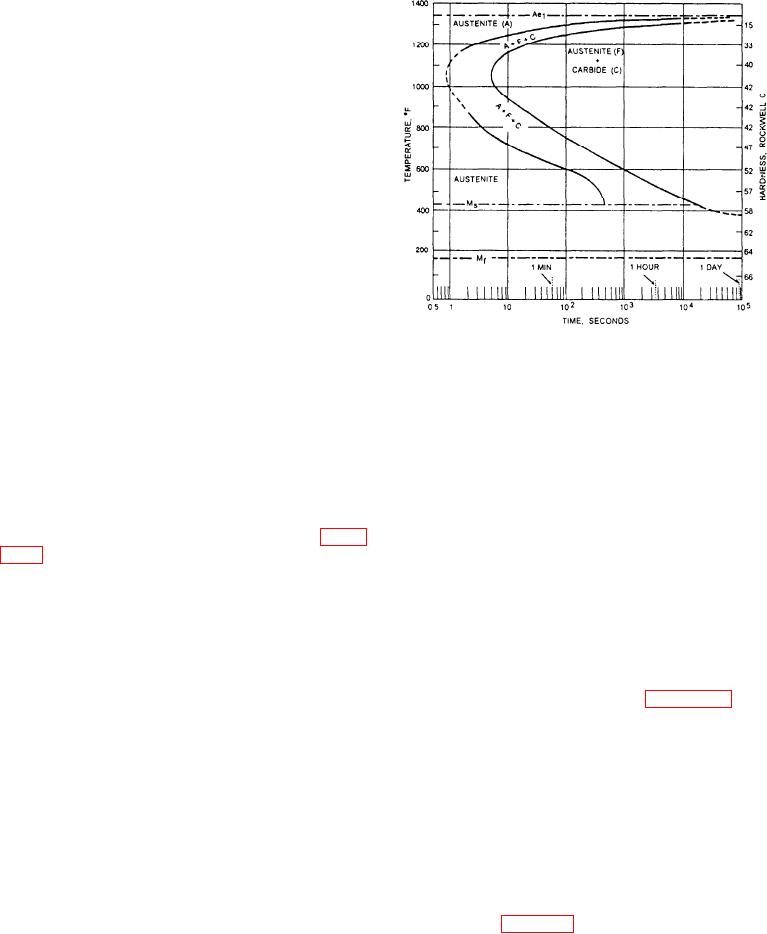

Figure 15-15.--Isothermal transformation diagram (S-curve)

As noted before, the very slow cooling of austenite

for eutectoid carbon steel.

to room temperature produces structures that are

salts. Occasionally, solid materials are used as

combination depends upon the percentage of carbon in

quenching mediums. In each instance, the quenching

the ahoy. With less than about 0.83 percent carbon, the

medium and the quenching procedure must be selected

structure is a combination of ferrite and pearlite. With

on the basis of the nature of the material being treated,

just about 0.83 percent carbon, the structure is entirely

the size and design of the piece, and the properties that

pearlitic. With more than 0.83 percent carbon, the

are required in the final product.

structure is a combination of pearlite surrounded by

Isothermal Transformation

cementite at the grain boundaries as shown in figure

The course of transformation of austenite when the

If the steel is cooled rapidly, a different structure

steel is quenched to and held at various constant

will result. The austenite will be retained until the

elevated temperature levels (isothermal transformation)

material reaches a temperature of about 430F. At this

is shown by a diagram known as the isothermal

point the transformation from austenite to a structure

transformation diagram (I-T diagram). This diagram is

called MARTENSITE begins. Martensite is a very hard

also called the Bain S-curve or the TTT diagram, for

and highly stressed structure. It is formed at the moment

time, temperature, and transformation. Such a diagram

gamma iron changes to alpha iron. Since gamma iron

can hold a great deal more carbon in solid solution than

I-T diagram of a steel is a map that charts the trans-

alpha iron can, the change from gamma iron to alpha

formation of austenite as a function of temperature and

iron causes a sudden dispersion of carbon. Because the

time and shows approximately how a particular steel

transformation from austenite is so rapid, carbon is

will respond to any rate of slow or rapid cooling from

trapped throughout the structure in this solid solution.

the austenite state. The products of this transformation

The rate of cooling is controlled by selecting an

will be discussed below.

appropriate quenching medium and cooling procedure.

PEARLITE: Austenite containing 0.83 percent of

Fresh water, brine, oil, and caustic soda in water are

carbon, cooled quickly to and held at 1,300F, does not

commonly used for rapid quenching. Slower cooling is

begin to decompose (transform) until after about 15

obtained by air cooling, by packing, and by furnace

minutes and does not completely decompose until after

cooling. Packing consists of burying the heated metal

in sand, ashes, or some other substance that is a poor

conductor of heat. Furnace cooling consists of shutting

below the critical temperature (Ac1), austenite is stable

off the heat and leaving the piece in the furnace so the

for a considerable length of time. The product of the

metal and the furnace cool together. Ferrous metals are

decomposition of austenite at this temperature is coarse

sometimes cooled in baths of molten lead or molten

pearlite of relatively low hardness. If the austenite is

15-17