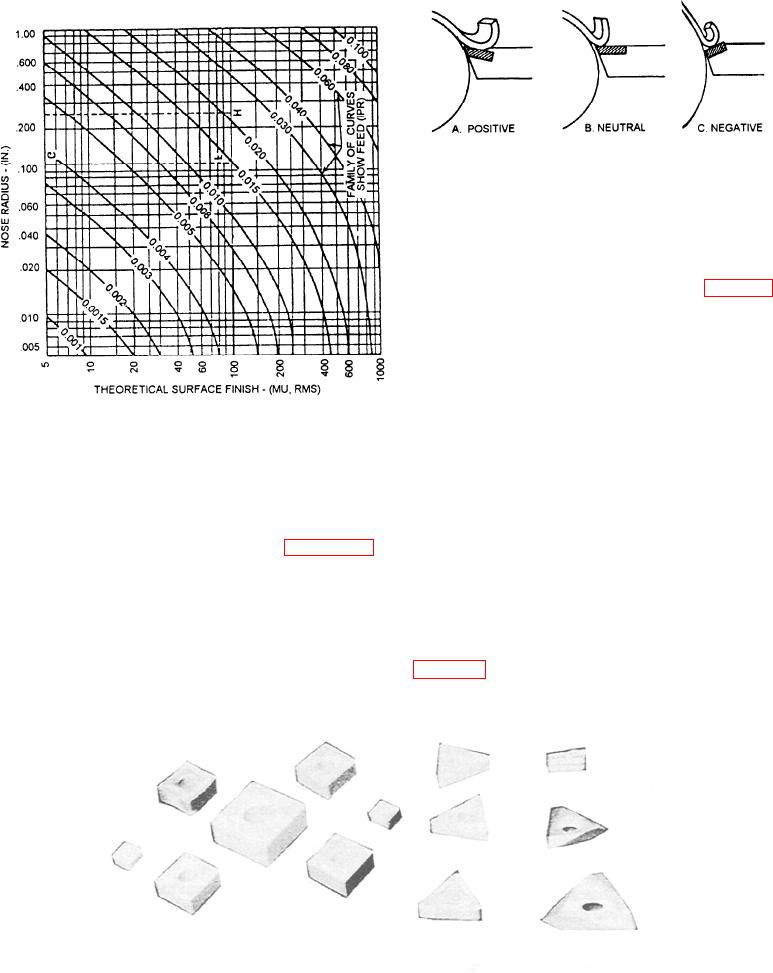

Figure 5-15.--Side view of rake angles.

for turning at a feed rate of 0.015 inch to obtain a

100 microinch finish. A 1/4-inch radius would be

required with a 0.020-inch feed rate.

are clamped in toolholders of various designs. Each

of these inserts has several cutting edges. After you

have used all of the edges, discard the insert.

Round inserts have the greatest strength and, like

large radius inserts, they offer higher feed rates with

Figure 5-13.--Surface finish vs nose radius chart.

Square inserts have lower strength and fewer

possible cutting edges than round tools, but they are

much stronger than triangular inserts

NOSE RADIUS.--Selecting the nose radius can be

Triangular inserts have the greatest versatility.

important because of tool strength, surface finish, or

For example, you can use them in combination

perhaps the need to form a fillet or radius on the work.

turning and facing operations where round or square

To determine the nose radius according to strength

Because the included angle between cutting edges is

Consider that the feed rate, depth of cut, and workpiece

less than 90, you also can use triangular inserts for

condition determine strength requirements.

tracing operations. The main disadvantages are their

reduced strength and fewer cutting edges per insert.

Large radii are strongest and can produce the best

finishes, but they also can cause chatter between tool

RAKE ANGLE.--When selecting rake angles

and workpiece. For example, the dashed line on the

chart shows that a 1/8-inch radius would be required

conditions. Use negative rake where there is maximum

28.479

Figure 5-14.--Indexable inserts.

5-11