inch per revolution. Any greater rate will subject, the

insert to excessive forces and may cause it to fracture.

GROUND SINGLE-POINT,

HIGH-SPEED CUTTING TOOLS

A single-point or single-edged cutting tool has

only one cutting edge as opposed to two or more on

other tools. Drill bits are multiple-edged cutters;

most lathe tools are single edged. To properly grind a

28.481

single-point cutting tool, you must know the relief

Figure 5-17.--Boring bars for carbide inserts.

angles, the rake angles, and the cutting edge angles

that are required for specific machines and materials.

You also must know what materials are generally used

Ceramic cutting tools are available as either solid

as cutting tools and how tools for various machines

ceramic or as ceramic coated carbide. They come in

differ.

several of the insert shapes available in cemented

carbides and they are secured in the toolholder by a

cl amp.

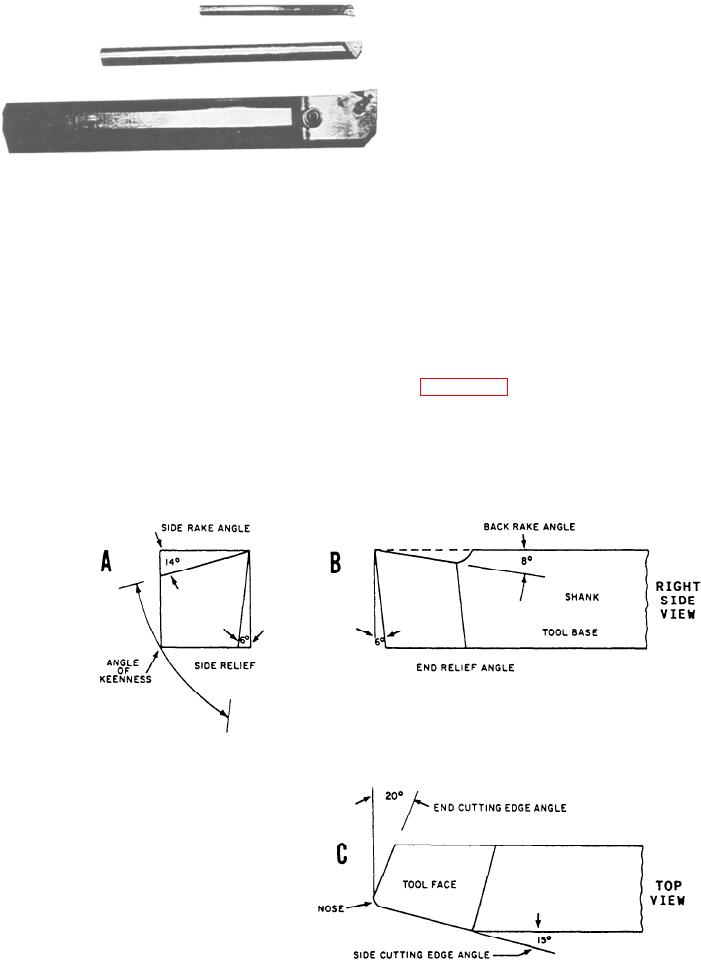

CUTTING TOOL TERMINOLOGY

Whenever you handle ceramic cutting tools, be

very careful because they are very brittle and will not

and surfaces we use to discuss single-point cutting

tools. Notice there are two relief angles and two rake

tolerate shock or vibration. Be sure your lathe setup

is very rigid and do not take interrupted cuts. Also be

angles and that the angle of keenness is formed by

grinding a rake angle and a relief angle. We'll discuss

sure the lathe feed rate does not exceed 0.015 to 0.020

Figure 5-18.--Applications of tool terminology.

5-13