Internal-threading tool: The internal-threading

(inside-threading) tool is the same as the threading

much smaller. Boring and internal-threading tools

may require larger relief angles when you use them in

small diameter holes.

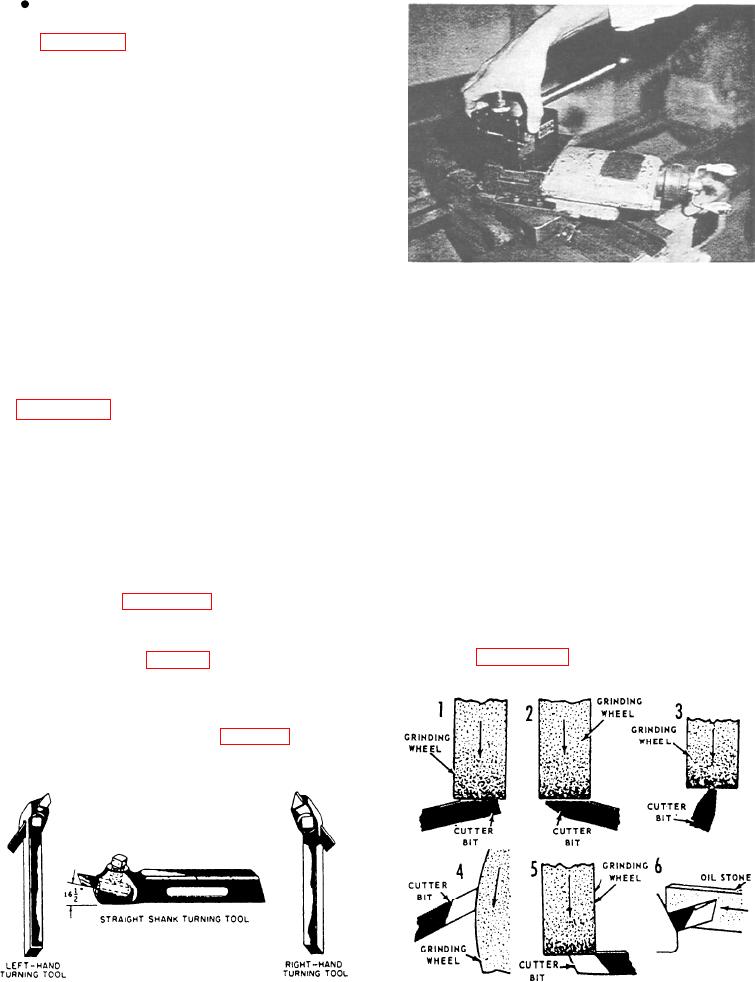

GRINDING HIGH-SPEED ENGINE

LATHE CUTTING TOOLS

Machining techniques and the materials being

machined limit the angles of a tool bit. However, when

grinding the angles, you also must consider the type of

toolholder and the position of the tool with respect to the

axis of the workpiece. The angular offset and the

28.302

angular vertical rise of the tool seat in a standard lathe

Figure 5-22.--Quick change toolpost and toolholder.

toolholder affect the cutting edge angle and the end

clearance angle of a tool when it is set up for machining.

recommended contours of several types of tools.

The position of the point of the tool bit with respect to

There are no definite guidelines on either the form or

the axis of the workpiece, whether higher, lower, or on

the included angle of the contour of pointed tool bits,

center, changes the amount of front clearance.

so you normally will forms the contour as you prefer.

For roughing cuts, the included angle of the contour

holders used in lathe work. Notice the angles at which

of pointed bits generally should be made as large as

the tool bits sit in the various holders. You must consider

possible and still provide clearance on the trailing side

these angles with respect to the angles ground in the tools

or end edge. Tools for threading, facing between

and the angle that you set the toolholder with respect to

centers, and parting have specific shapes because of

the axis of the work. Also, notice that a right-hand

the form of the machined cut or the setup used.

toolholder is offset to the LEFT and a left-hand

The basic steps are similar when you grind a

toolholder is offset to the RIGHT. For most machining

single-edged tool bit for any machine. The difference

operations, a right-hand toolholder uses a left-hand

is in shapes and angles. Machinery's Handbook

turning tool and a left-hand toolholder uses a right-hand

shows the recommended angles under the section on

single-point cutting tools. Use a coolant when you

help you understand this apparent contradiction. Also,

grind tool bits. Finish the cutting edge by honing it on

take into consideration that if you use a quick change

and your back rake angle will change.

The contour of a cutting tool is formed by the side

cutting edge angle and the end cutting edge angle of

the tool. Views A through G of fig. 5-20 show the

Figure 5-23.--Grinding and honing a lathe cutter bit.

Figure 5-21.--Standard lathe toolholders.

5-17