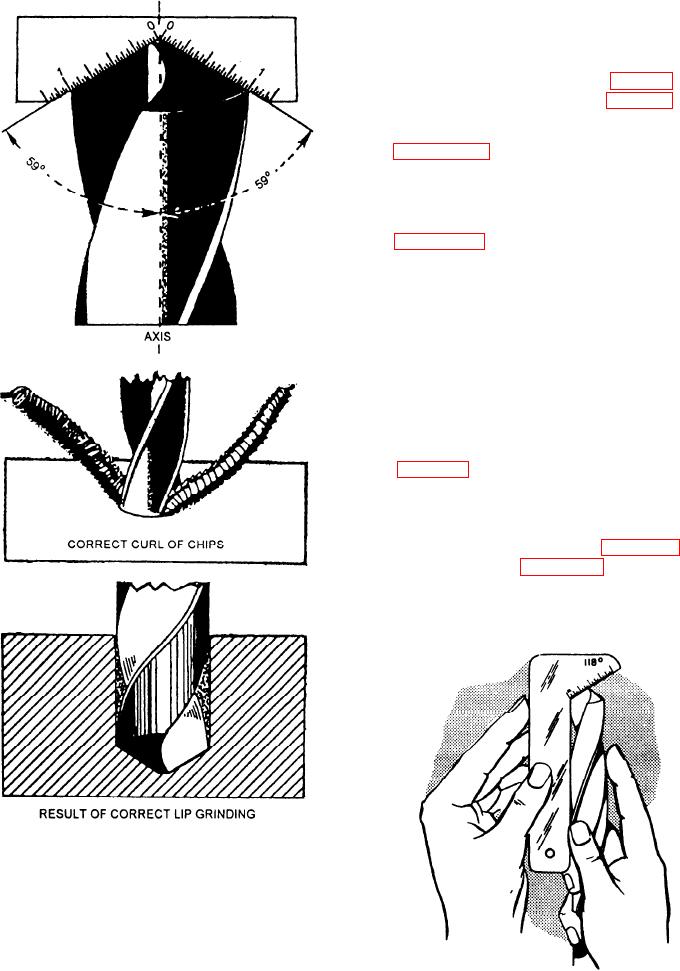

angles must be equal and correctly sized, (2) cutting

lips must be of equal length, (3) the clearance behind

the cutting lips must be correct, and (4) the chisel-edge

angle must be correct. All four are equally important

when grinding either a regular point (fig. 5-30) used for

drill hard and tough materials.

grinding and how equal drill point angles and two

equal length cutting lips help achieve correct drill

results.

grinding. The drill-point gauge is being held against

the body of the drill and has been brought down to

where the graduated edge of the gauge is in contact

with one cutting edge. In this way, both the drill-point

angle and the length of the cutting edge (or lip) are

checked at the same time. The process is repeated for

the other side of the drill.

You determine lip clearance behind the cutting lip

at the margin by inspection. This means you look at

the drill point and approximate the lip-clearance angle

it to the same angle that has been set on a protractor.

The lip-clearance angle is not necessarily a definite

angle, but it must be within certain limits. Notice that

angle in the range is used, however, lip clearance

should be the same for both cutting lips.

Figure 5-32.--Grinding drill lip correctly.

it may be softened. You may also want to dip the

chisel in a coolant.

SHARPENING TWIST DRILLS

When grinding twist drills, it is most important

Figure 5-33.--Checking the drill point angle cutting edge.

that you meet the following criteria: (1) drill point

5-21