Several types of tools are required for shaper or

should use to grind a round-nose turning tool. We'll

planer operations. Although the types differ

describe each of the steps in the following paragraphs:

considerably in shape, the same general rules govern

1. Grind the left side of the tool, holding it at the

the grinding of each type.

correct angle against the wheel to form the

To be sure you have an efficient cutting tool, grind

necessary side clearance. Use the coarse

the side relief and end relief of the tool to give a

grinding wheel to remove most of the metal,

projecting cutting edge. If the clearance is insufficient,

then finish on the fine grinding wheel. (If you

the tool bit will rub the work, causing excessive heat and

grind the cutting edge on the periphery of a

producing a rough surface on the work. If the tool is

wheel less than 6 inches in diameter, it will be

given too much relief, the cutting edge will be weak and

undercut and will not have the correct angle.)

will tend to break during the cut. The fRont and side

Keep the tool cool while you grind it.

clearance angles should seldom exceed 3 to 5.

In addition to relief angles, the tool bit must slope

2. Grind the right side of the tool, holding it at

away from the cutting edge. This slope is known as

the required angle to form the right side.

side rake and reduces the power required to force the

3. Grind the radius on the end of the tool. A

cutting edge into the work. The side rake angle is

small radius (approximately 1/32 inch) is

usually 10 or more, depending upon the type of tool

preferable because a large radius may cause

and the metal being machined. Roughing tools

chatter. Hold the tool lightly against the wheel

should have no back rake although a small amount is

and turn it from side to side to produce the

generally required for finishing.

desired radius.

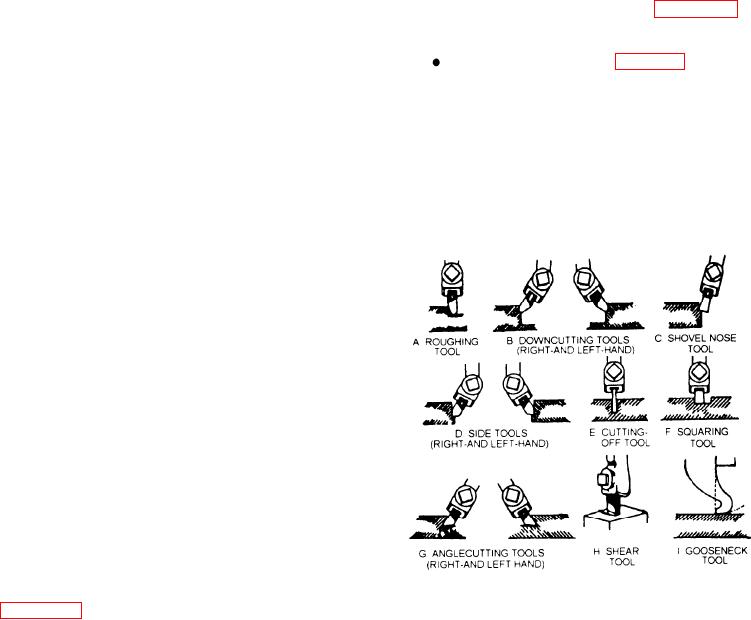

The shape and use of various standard shaper and

planer cutting tools are illustrated in figure 5-24 and

4. Grind the front of the tool to the desired front

described in the following paragraphs:

clearance angle.

5. Grind the top of the tool, holding it at the

very efficient for general use and is designed to take

required angle to obtain the necessary side

heavy cuts in cast iron or steel. You will generally

rake and back rake. Try not to remove too

grind it for left-hand operation as illustrated. For

much of the metal. The more metal you leave

special applications, you can reverse the angles for

on the tool, the better the tool will absorb the

right-hand cuts. Do not give this tool any back rake

heat produced during cutting.

although the side rake may be as much as 20 for soft

6. Hone the cutting edge all around and on top

metals. Do finishing operations on small flat pieces

with an oilstone until you have a keen cutting

with the roughing tool if a fine feed is used.

edge. Use a few drops of oil on the oilstone.

Honing will improve the cutting quality of the

tool, produce a better finish on the work, and

cause the cutting edge to stand up much longer

than one that is not honed. The cutting edge

should be sharp in order to shear off the metal

rather than tear it off.

SHAPER AND PLANER TOOLS

Shaper and planer cutting tools arc similar in

shape to lathe tools but differ mainly in their relief

angles. These tools are held practically square with

the work and do not feed during the cut; therefore,

relief angles are much less than those in turning

operations. The nomenclature of shaper and planer

tools is the same as that for lathe tools; and the

elements of the tool, such as relief and rake angles,

are in the same relative positions as those shown in

Figure 5-24.--Standard shaper and planer tools.

5-18