applications. Each of the types shown is described in

the following paragraphs:

Left-hand turning tool: Grind this tool for

machining work by feeding it from left to right as

the right side of the tool and the top of the tool slopes

down away from the cutting edge.

Round-nose turning tool: This tool is for

general all-round machine work and is used to make

light roughing cuts and finishing cuts. You should

usually grind the top of the cutter bit with side rake so

the tool may be fed from right to left. You may

sometimes grind the cutter bit flat on top so you can

Right-hand turning tool: This is just the

opposite of the left-hand turning tool and is designed

a radius of from 1/64 to 1/32 inch in turning

to cut when fed from right to left (fig. 5-20, view C).

operations.

The cutting edge is on the left side. This is an ideal

tool for roughing cuts and general all-round machine

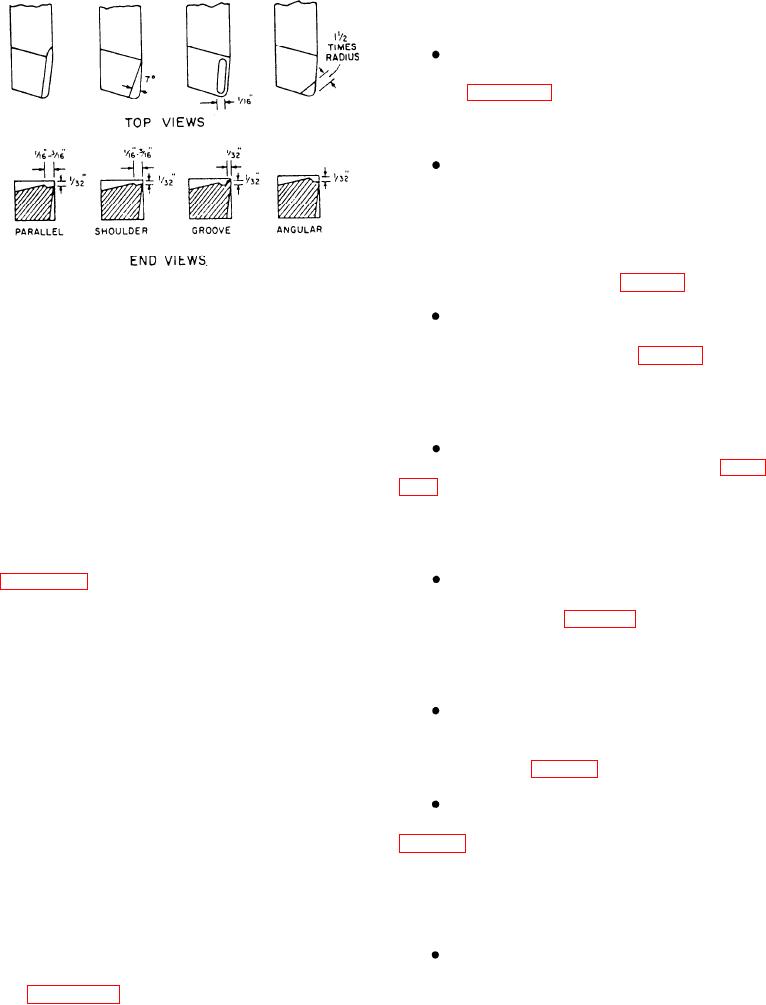

GROUND-IN CHIP BREAKERS

work.

Left-hand facing tool: Use this tool for facing

surface of the tool to reduce or prevent the formation

on the left-hand side of the work as shown in figure

of long and dangerous chips. The chip breaker will

5-20, view D. The direction of feed is away from the

cause the chips to curl up and break into short, safe,

lathe center. The cutting edge is on the right-hand

manageable chips. You normally grind chip breakers

side of the tool and the point of the tool is sharp to

on roughing tools, but you can grind them on

permit machining a square corner.

finishing tools used to machine soft ductile metals.

Threading tool: Grind the point of the

threading tool to a 60 included angle to machine

breakers.

The dimensions given are general and can be

you should grind the top of the tool flat and leave

modified to compensate for the various feed rates,

clearance on both sides of the tool so it will cut on

depths of cut, and types of material being machined.

both sides.

Grind the groove-type chip breaker carefully to

Right-hand facing tool: This tool is just the

prevent it from coming too close to the cutting edge;

opposite of the left-hand facing tool. Use it to face

that reduces the life of the tool because there is less

the right end of the work and to machine the right side

support of the cutting edge. You can use the diamond

w h e e l on a chip breaker grinder to grind

carbide-tipped tools. Grind high-speed tools with an

Square-nosed parting (cut-off) tool: The

aluminum oxide grinding wheel. You can use a bench

principal cutting edge of this tool is on the front. (See

grinder for this purpose if you dress the wheel until it

fig. 5-20, view G.) Both sides of the tool must have

has a sharp edge. Or, you can clamp the tool in a

enough clearance to prevent binding and should be

universal vise that you can set to compound angles on

ground slightly narrower at the back than at the

a surface or tool and cutter grinder.

cutting edge. Use this tool to machine necks and

grooves, square corners, and to cut off.

SHAPES OF HIGH-SPEED ENGINE

LATHE CUTTING TOOLS

Boring tool: Usually, you should grind a

boring tool in the same shape as the left-hand turning

tool so the cutting edge is on the front side of the

cutter bit and may be fed in toward the headstock.

ground high-speed lathe tool cutter bits and their

5-15