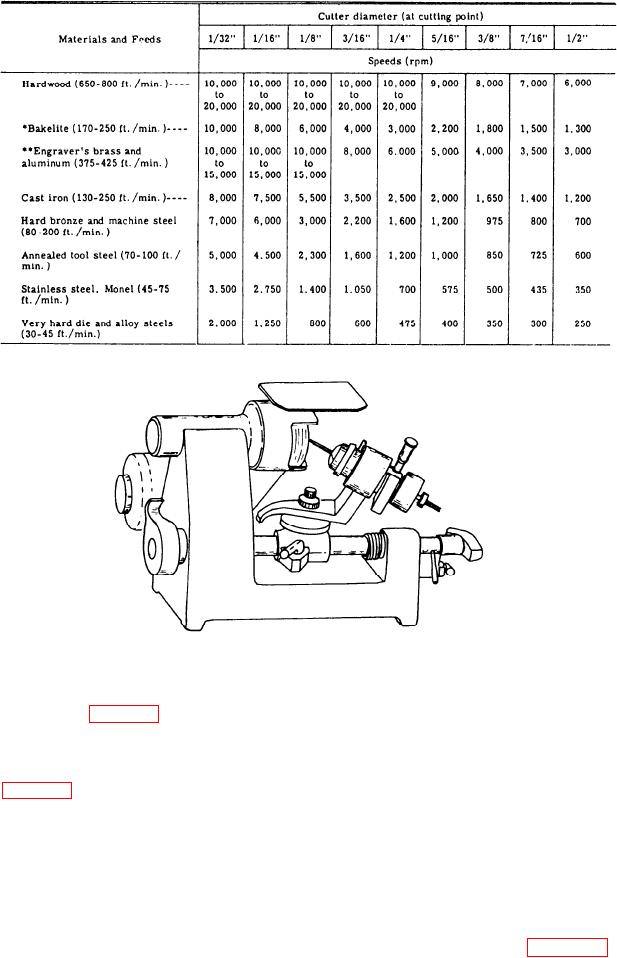

Table 9-2.--Cutter Speeds

CUTTER SPEEDS

finish possible at higher speeds. With experience you

will know when the cutter is running at its maximum

The speeds listed in table 9-2 represent typical

efficiency.

speeds for given materials when you are using a

high-speed steel cutter. If you are using a carbide cutter,

GRINDING CUTTERS

refer to your operators manual for the correct speeds.

When using table 9-2, keep in mind that the speeds

Improper grinding of cutters causes most of the

recommended will vary greatly with the depth of cut,

problems in using very small cutters on small lettering.

and particularly with the rate at which you feed the

The cutter point must be accurately sharpened.

cutter through the work.

Problems usually occur because the point is burned, the

Run the cutters at the highest speeds possible

flat is either too high or too low, or perhaps the clearance

without burning them, and remove stock with several

does not run all the way to the point. Stone off the flat

light, fast cuts rather than one heavy, slow cut. When

with a small, tine oilstone to make the cutting edge

you cut steel and other hard materials, start with a slow

keener.

speed and work up to the fastest speed the cutter will

stand without losing its cutting edge. Sometimes you

with interchangeable grinding wheels for carbide and

may have to sacrifice cutter life to obtain the smoother

high-speed steel cutters. We will discuss grinding-high

9-17