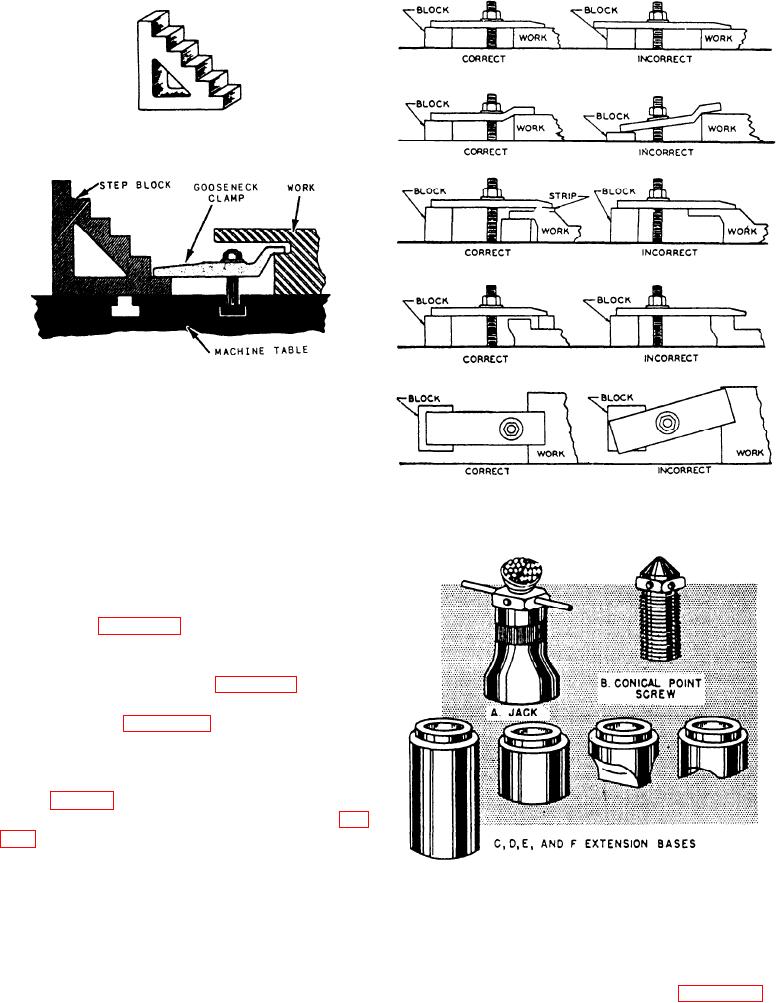

Figure 9-15.--Application of step block and clamp.

Holding the Work

The various accessories used to hold planer or

shaper work may make the difference between a

Figure 9-16.--Correct and incorrect clamp applications.

superior job and a poor job. There are no set rules on

the use of planer accessories to clamp down a piece of

work--results will depend on your ingenuity and

experience.

One way to hold down work on the worktable is by

using clamps atached to the worktable by bolts inserted

in the T-slots. Figure 9-14 shows a step block that you

can use with clamps when you need to clamp an

irregularly shaped piece of work to the planer table. One

accurately machined step block is used with a

incorrect ways to apply clamps.

You can use jacks of different sizes to level and

support work on the planer table. The conical point

screw (fig. 9-17, B) replaces the swivel pad-type screw

for use in a comer. You can use extension bases (fig.

9-17, C, D, E, and F) to increase the effective height of

the jack

Figure 9-17.--Planer jack and extension bases.

PANTOGRAPHS

workpiece. You can use it to engrave flat and uniformly

The pantograph (engraving machine) is essentially

curved surfaces.

a reproduction machine. It is used in the Navy to

There are several different models of engraving

engrave letters and numbers on label plates, to engrave

and graduate dials and collars, and in other work that

requires the exact reproduction of a flat pattern on the

shows one model that mounts on a bench or a table top

9-14