28.227

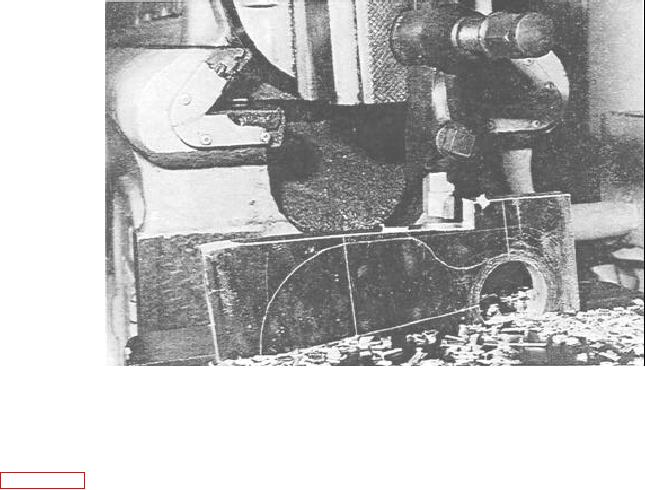

Figure 9-11.--Shaping irregular surfaces.

tooth space in the form of a plain rectangular groove,

which external and internal keyways are cut to produce

then finish it with a tool ground to the tooth's finished

the greatest strength. When you cut a keyway in the

contour and size.

gear, set the downfeed micrometer collar to zero at the

To machine a rack, use the following sequence of

point where the cutting tool first touches the edge of the

operations:

hole. First, remove the crown, X, from the shaft to

produce a flat whose width is equal to the width of the

1. Clamp the work in the vise or to the table.

key. Then, make a cut in the shaft to depth 2. The

2. Position a squaring tool, which is narrower

distance of Y plus Z is equal to the height of the key that

is to lock the two parts together.

than the required tooth space, so the tool is

centered on the first tooth space to be cut.

SHAPING IRREGULAR SURFACES.--To

machine irregular surfaces, use form ground tools and

3. Set the graduated dial on the crossfeed screw

feed the cutting tool vertically by hand while using

to zero, and use it as a guide to space the teeth.

power feed to move the work horizontally. A gear rack

4. Move the toolslide down until the tool just

is an example of work you might shape by using form

tools. You can use the toolhead feed to shape work such

touches the work, and lock the graduated collar

as concave and convex surfaces. When you machine

on the toolslide feed screw.

irregular surfaces, you have to pay close attention

5. Start the machine and feed the toolslide down

because you control the cutting tool manually. Also,

slightly less than the whole depth of the tooth,

you should lay out the job before you machine it to

provide reference lines. You also should take roughing

using the graduated collar as a guide, and rough

cuts to remove excess material to within 1/16 inch of

out the first tooth space.

the layout lines.

6. Raise the tool to clear the work and move the

You can cut RACK TEETH on a shaper as well as

crossfeed a distance equal to the linear pitch of

on a planer or a milling machine. During the machining

the rack tooth by turning the crossfeed lever.

operation, you may either hold the work in the vise or

Rough out the second tooth space, and repeat

clamp it directly to the worktable. After you mount and

position the work, use a roughing tool to rough out the

this operation until all spaces are roughed out.

9-10