extent in planer and shaper work Tool bits are available

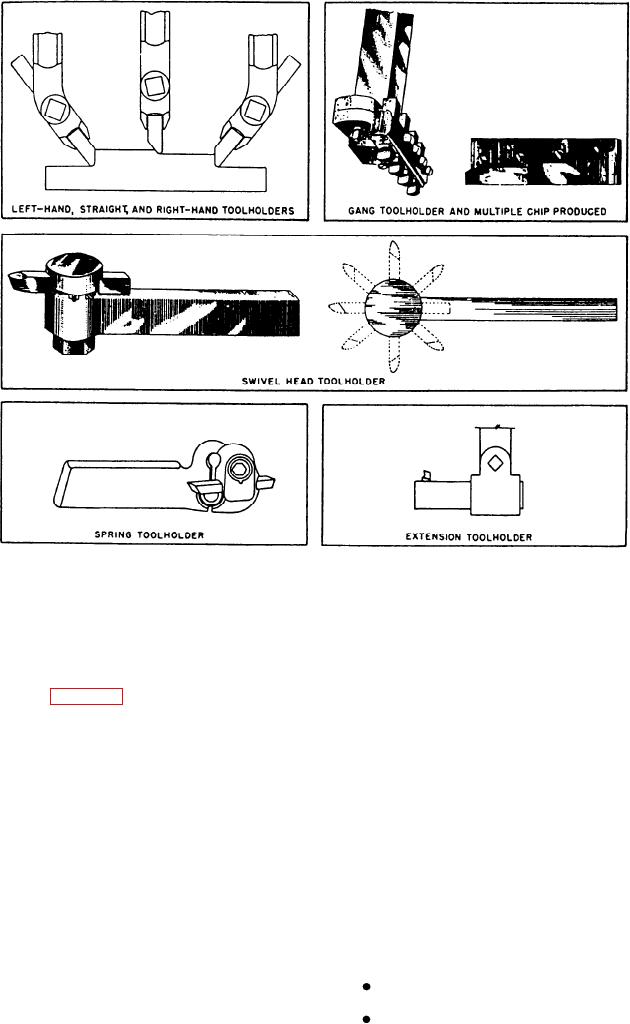

amount of vibration. This toolholder is particularly

in different sizes and are hardened and cut to standard

good for use with formed cutters, which have a tendency

to chatter and dig into the work.

lengths to fit the toolholders. The toolholders that you

will most commonly use are described in the following

5. Extension toolholders are adapted to cut internal

keyways, splines, and grooves on the shaper. You can

adjust the extension arm of the holder to change the

1. Right-hand, straight, and left-hand toolholders

exposed length and the radial position of the tool.

used in most common shaper and planer operations.

Chapter 5 contains procedures used to grind shaper

2. Gang toolholders especially adapted to surface

and planer tool bits for various operations.

large castings. With a gang toolholder, you make

multiple cuts with each forward stroke of the shaper.

Each tool takes a light cut and there is less tendency to

Operations

"break out" at the end of a cut.

3. Swivel head toolholders are universal, patented

Before beginning any job on the shaper, you should

holders that you can adjust to place the tool in various

thoroughly study and understand the blueprint or

radial positions. This feature allows you to convert the

drawing from which you are to work. In addition, you

swivel head toolholder to a straight, right-hand, or

should take the following precautions:

left-hand holder at will.

Make certain that the shaper is well oiled.

4. Spring toolholders have a rigid, U-shaped

spring that lets the holder cap absorb a considerable

Clean away ALL chips from previous work.

9-5