28.462

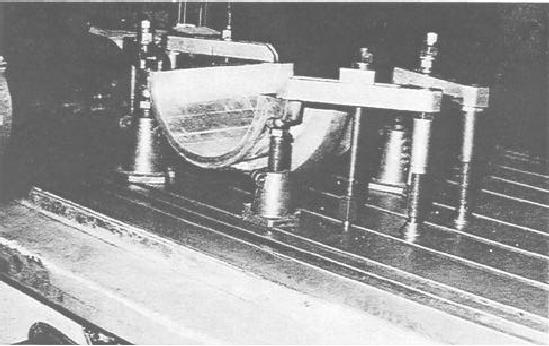

Figure 8-13.--Line shaft bearing that has had the "cheeks" or oil reservoir grooves cut into it.

direction selection lever position remains unchanged.

as many as 23 different threads, both standard and

Allow the machine to run in this direction until the

metric.

cutting tool has returned to its starting point. Advance

To cut threads with these machines, use a system

the cutter to cut the thread a little deeper, set the

spindle motor to run in forward, then make another

leads. Secure a single-point tool in a suitable

cutting pass. Follow this procedure until the thread is

toolholder and mount the toolholder in the spindle of

completed. A boring bar with a micro-adjustable tool

the machine. While you cut threads, keep the spindle

bit or a small precision head is ideal for this operation.

locked in place. The saddle, carrying the workpiece,

It allows fast, easy adjustment of the tool depth and

advances at a rate determined by the change gear

accuracy and control of the depth setting.

combination, Feeding, in conjunction with the

spindle rotation in the low back gear range, produces

When you set up to cut threads, remove the thread

the threads.

lead access covers and set up the correct gear train

combination as prescribed by the manufacturer's

technical manual. After you have set up the gear

Cut the thread a little at a time in successive

train, tighten the nuts on the arm clamp to lock the

passes. The thread profile depends on how the cutting

sliding arm. Be sure to replace the retaining washers

tool is ground. When you have completed the first

on all the studs and lock them with the screws

pass, back the cutting tool off a few thousandths of an

p r o v i d e d with the machine. Refer to the

inch to avoid touching the workpiece on the return

manufacturer's technical manual for the machine you

movement. Then, reverse the spindle driving motor.

are using for the correct gear arrangement.

This causes the saddle direction to reverse while the

8-11