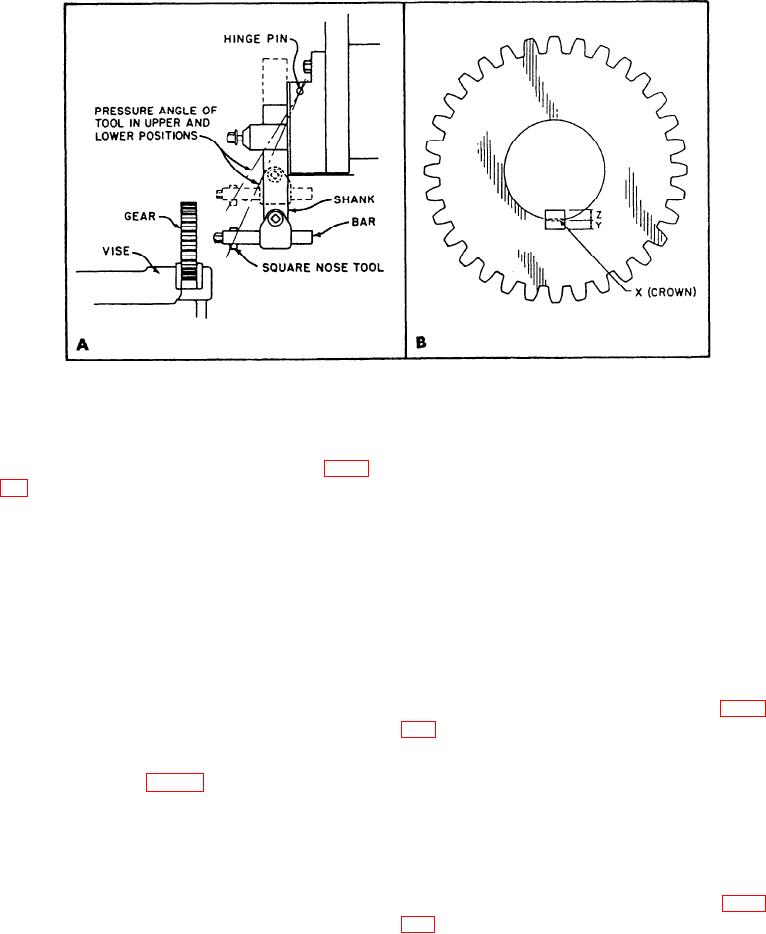

Figure 9-10.--Internal keyway: A. Shaping an internal keyway in a gear. B. Depth of keyways.

tools, and the cutting point will tend to spring away from

1. Lay out the centerline, the keyway width, and

the work unless you take steps to compensate. The

the clearance hole centers, as shown in view A of figure

9-9. Drill the clearance holes.

keyway MUST be in line with the axis of the gear. Test

the alignment with a dial indicator by taking a reading

2. Position the shaft in the shaper vise or on the

across the face of the gear. Swivel the vise slightly to

worktable so that it is parallel to the ram. Use a

correct the alignment if necessary.

machinist's square to check the centerline on the end of

the shaft to be sure it is perpendicular to the surface of

The bar of the square-nose toolholder should not

the worktable. This ensures that the keyway layout is

extend further than necessary from the shank;

exactly centered at the uppermost height of the shaft and

otherwise, the bar will have too much spring and will

that the keyway is centered on the centerlines of the

allow the tool to be forced out of the cut.

shaft.

The extension toolholder should extend as far as

3. Adjust the stroke and the position of the ram so

practical below the clapper block, rather than in the

the forward stroke of the cutting tool ends at the center

position shown by the dotted lines in view A of figure

of the clearance hole. (If you are cutting a blind keyway,

9-10. The pressure angle associated with the toolholder

be sure the cutting tool has enough clearance at the end

in the upper position may cause the pressure of the cut

of the return stroke so the tool will remain in the keyway

to open the clapper block slightly and allow the tool to

slot.) (See view B of fig. 9-9.)

leave the cut. In the lower position, the pressure angle

4. Position the work under the cutting tool so that

is nearly vertical and prevents the clapper block from

the tool's center is aligned with the centerline of the

opening. Another method to prevent the clapper block

keyway. (If the keyway is more than 1/2 inch wide, cut

from opening is to mount the tool in an inverted

a slot down the center and shave each side of the slot

position.

until you get the proper width.

With the cutting tool set up as in view A of figure

5. Start the shaper and use the toolhead slide to

9-10, center the tool within the layout lines in the usual

feed the tool down to the depth required, as shown on

manner, and make the cut to the proper depth while

the graduated collar.

feeding the toolhead down by hand. If you mount the

tool in an inverted position, center the tool within the

SHAPING AN INTERNAL KEYWAY.--To cut

layout lines at the top of the hole, and make the cut by

an internal keyway in a gear, you will have to use

feeding the toolhead upward.

extension tools. These tools lack the rigidity of external

9-9