7. Replace the roughing tool with a tool ground

to size for the desired tooth form, and align the

tool.

8. Adjust the work so the tool is properly aligned

with the first tooth space that you rough cut.

9. Set the graduated dial on the crossfeed screw

at zero and use it as a guide to space the teeth.

10. Move the toolslide down until the tool just

touches the work, and lock the graduated collar

on the toolslide feed screw.

11. Feed the toolslide down the whole depth of the

tooth, using the graduated collar as a guide, and

finish the first tooth space.

12. Raise the tool to clear the work and move the

crossfeed a distance equal to the linear pitch of

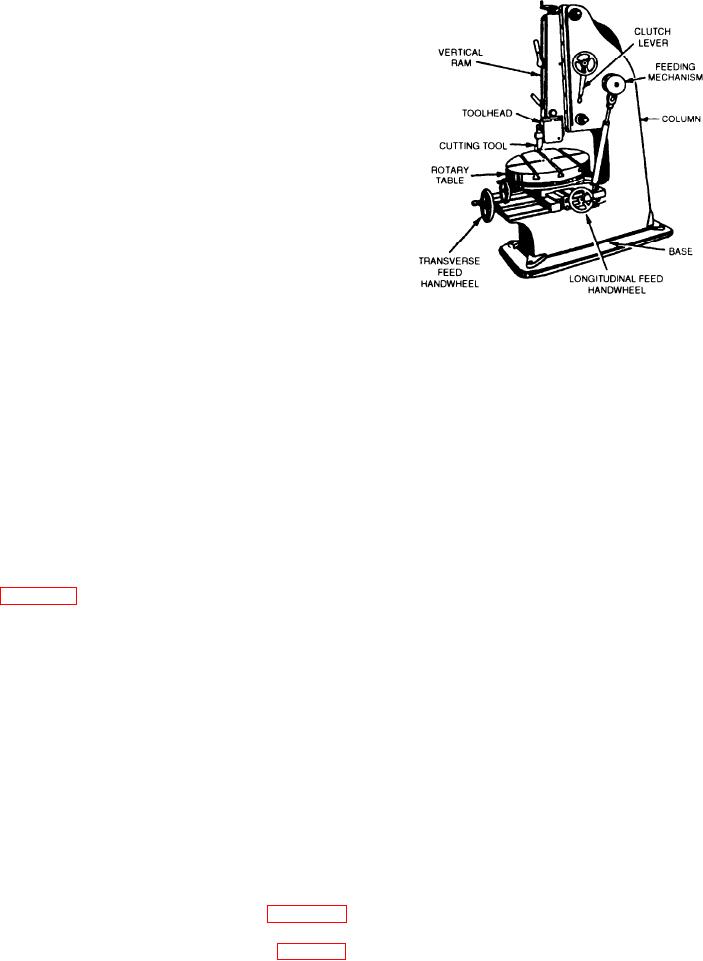

Figure 9-12.--Vertical shaper.

the rack tooth by turning the crossfeed lever.

13. Finish the second tooth space; then measure the

locations, but all of them will have the same basic

thickness of the tooth with the gear tooth

functions and capabilities. The speed of the ram is

vernier caliper. Adjust the toolslide to

adjustable to allow for the various materials and

compensate for any variation indicated by this

machining requirements. Speed is expressed in either

measurement.

strokes per minute or feet per minute, depending on the

14. Repeat the process of indexing and cutting

particular model. You also may adjust the length and

until you have finished all of the teeth.

the position of the ram stroke. Automatic feed for the

cross and longitudinal movements, and on some models

Use the following procedure to machine irregular

the rotary movement, is provided by a ratchet

surfaces that have CONVEX and/or CONCAVE radii.

mechanism, gear box, or variable speed hydraulic

On one end of the work, lay out the contour of the

system. Again, the method depends on the model. You

finished job. When you shape to a scribed line, as shown

may hold the work in a vise mounted on the rotary table,

clamp it directly to the rotary table, or hold it by special

1/16 inch of the line. You can do this by making a series

fixtures. The square hole in the center of a valve

of horizontal cuts using automatic feed and removing

handwheel is an example of work that can be done on a

excess stock. Use a left-hand cutting tool to remove

machine of this type. The sides of the hole are cut on a

stock on the right side of the work and a right-hand

slight angle to match the angled sides of the square on

cutting tool to remove stock on the left side of the work

the valve stem. If this hole were cut by using a broach

When 1/16 inch of metal remains above the scribed line,

or an angular (square) hole drill, the square would wear

take a file and bevel the edge to the line. This will

prematurely due to the reduced area of contact between

eliminate tearing of the line by the breaking of the chip.

the straight and angular surfaces.

Starting at the right-hand side of the work, set the

automatic feed so the horizontal travel is rather slow.

Feed the tool vertically by hand to take finishing cuts

PLANERS

and produce a smooth contoured surface.

Planers are rigidly constructed machines,

VERTICAL SHAPERS

particularly suitable for machining long cuts on large

and heavy work In general, planers and shapers can be

used for similar operations. However, the reciprocating

motion of planers is provided by the worktable (platen),

is especially adapted to slot internal holes or keyways

while the cutting tool is fed at a right angle to this

motion. Like the shaper, the planer cuts only on the

reciprocates up and down. To do angular slotting, tilt

forward stroke, after which the table makes a quick

the ram to the required angle. Different models of

return to bring the work into position for the next cut.

machines will have their control levers in different

9-11