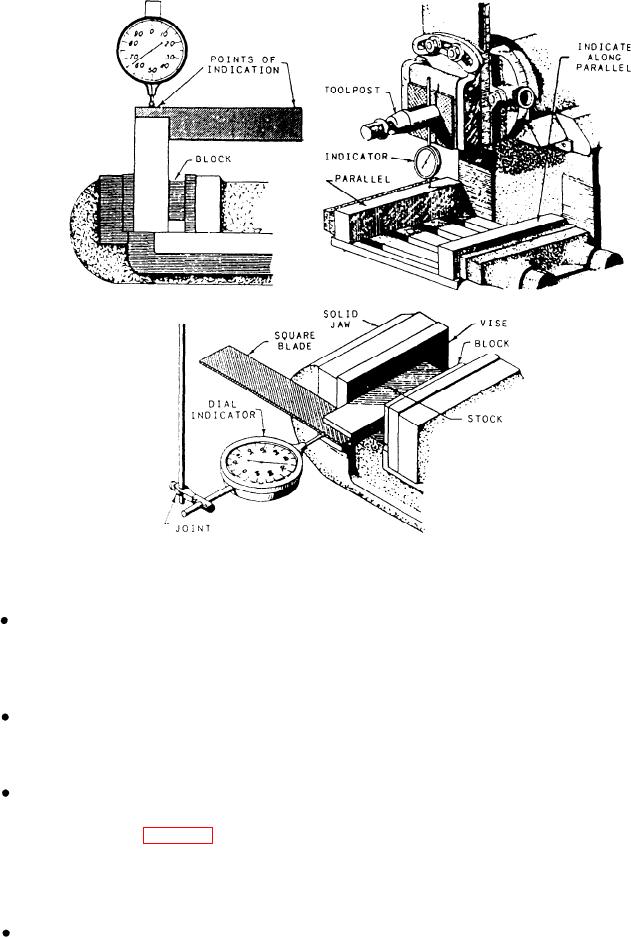

Figure 9-8.--Squaring the table and the vise.

SPEEDS AND FEEDS.--You will set up the

Be sure the cutting tool is set properly; otherwise,

shaper to cut a certain material similar to the way you

the tool bit will chatter. Set the toolholder so the

set up other machine tools, such as drill presses and

tool bit does not extend more than about 2 inches

lathes. First, determine the approximate required

below the clapper box.

cutting speed, then determine and set the necessary

machine speed to produce your desired cutting speed.

Be sure the piece of work is held rigidly in the

On all of the machine tools we discussed in the previous

vise to prevent chatter. You can seat the work by

chapters, cutting speed was directly related to the speed

tapping it with a babbitt hammer.

(rpm) of the machine's spindle. You could determine

Test the table to see if it is level and square. Make

what spindle rpm to set by using one formula for all

these tests with a dial indicator and a machinist's

brands of a particular type of machine. The setup for a

shaper is slightly different. You still relate cutting speed

or the vise is off parallel, check for dirt under the

to machine speed through a formula, but the formula

depends on the brand of machine that you operate. This

vise or improper adjustment of the table support

is because some manufacturers use a slightly different

bracket.

formula to compute cutting speed than others. To

Adjust the ram for length of stroke and position.

determine the correct formula for your machine, consult

The cutting tool should travel 1/8 to 1/4 inch past

the operator's manual provided by the manufacturer.

the edge of the work on the forward stroke and

The following discussion explains basically how

3/4 to 7/8 inch behind the rear edge of the work

the operation of a shaper differs from the operation of

other machine tools. It also explains how to determine

on the return stroke.

9-6