worktable and provides a means of rapid graduation and

of engraving the faces of disks.

USING A CIRCULAR COPY PLATE

You should be able to use a circular copy plate

efficiently to engrave several similar workpieces with

single characters used consecutively. For example, you

can use the following setup to engrave 26 similar

workpieces with a single letter, but with each piece

having a different letter.

so the numbers are centered on the required graduation

1. Set the workpiece conveniently on the work-

marks.

table and clamp two aligning stops in place. Do not

remove these stops until the entire job is completed.

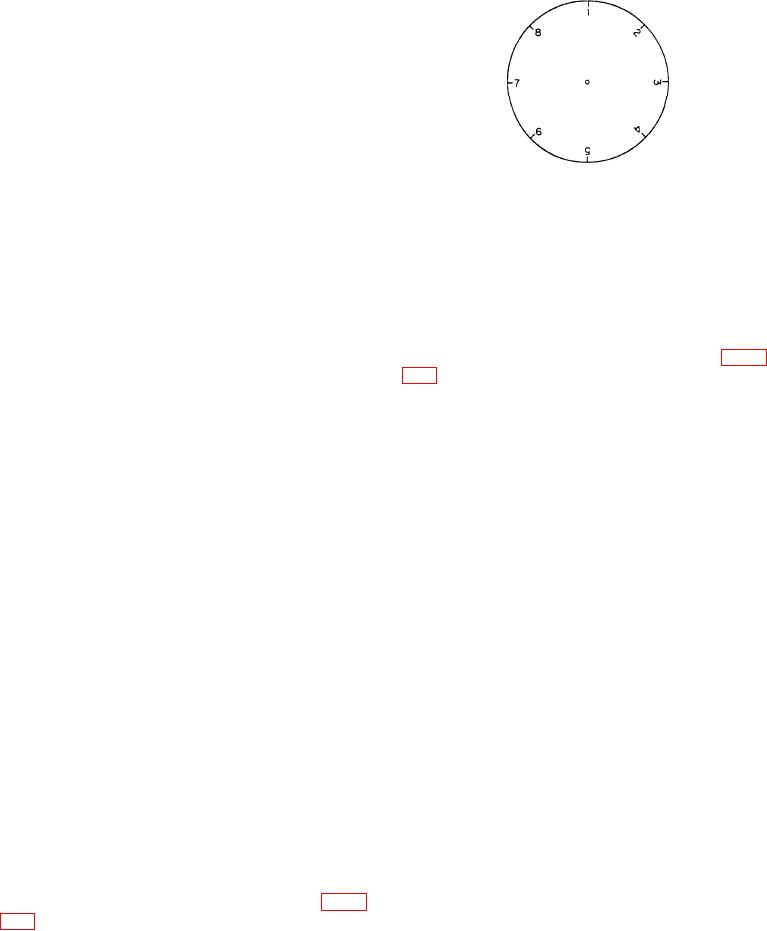

ENGRAVING A DIAL FACE

2. Set the circular plate on the copyholder so that

the plate can be rotated by hand. Check to ensure that

Use a rotary table and a circular copy plate to

the indexing pawl engages the notch on the rim so the

engrave a dial face, such as the one shown in figure

plate will be steady while you trace each character.

9-31. Note that the figures on the right side of the dial

are oriented differently from those on the left side; this

3. Set the machine for the required reduction and

illustrates the usual method of positioning characters on

speed, and adjust the worktable so the spindle is in

dials. The graduations are radially extended from the

position over the workpiece.

center of the face. The graduations also divide the dial

4. Clamp the first workpiece in place on the work-

into eight equal divisions.

table. (The aligning stops, step 1, ensure accurate

Use the following procedures to set up and engrave

positioning.)

a dial face:

5. Rotate the circular plate until the letter A is under

1. Set the reduction required. Use the size of the

the tracing stylus and the index pawl is engaged in the

copy on the circular copy plate and the desired size of

notch.

the numerals on the work as the basis to compute the

6. Engrave the first piece with the letter A. Check

reduction.

the operation for required adjustments of the machine.

2. Set the copy plate on the copyholder and be

7. After you have finished the first piece, remove

sure it is free to rotate when the ratchet is disengaged.

it from the machine. Do not change the alignment of the

3. Mount a rotary table on the worktable of the

aligning stops (step 1), the worktable, or the copy-

engraver. Position the dial blank on the rotary table so

holder. Place the second workpiece in the machine.

the center of the dial coincides with the center of the

Index the circular plate to the next letter and repeat the

rotary table. Clamp the dial blank to the rotary table.

process.

4. Place the tracing stylus in the center of the

8. Continue to load the workpieces, index the plate

circular copy plate and adjust the worktable so the

to the next character, engrave, and remove the work

center of the dial is directly under the point of the cutter.

until you have finished the job.

5. Rotate the copy plate until the copy character

used to make graduation marks is aligned with the

ENGRAVING A GRADUATED COLLAR

center of the copy plate and the center of the work. Set

the stylus in this mark. Now, by feeding the worktable

To engrave a graduated collar, as shown in figure

straight in toward the back of the engraver, adjust the

9-29, use a forming guide and indexing attachment. You

table so the cutter will cut the graduation to the desired

also can use the circular copy plate to speed up the

length.

numbering process. After you engrave each graduation,

index the work to the next division until you finish the

6. Start the machine and adjust the engraver

graduating. When you engrave numbers with more than

worktable vertically for the proper depth of cut. Then,

one digit, offset the work angularly by rotating the work

clamp the table to prevent misalignment of the work.

9-22