To select the proper work speed, take a cut with the

work speed set at 50 fpm. If the wheel acts too soft,

decrease the work speed. If the wheel acts too hard,

increase the work speed.

Wheel speed and work speed are closely related.

Usually, you can adjust one or both to get the most

suitable combination.

DEPTH OF CUT

The depth of cut depends on such factors as the

material from which the work is made, heat treatment,

wheel and work speed, and condition of the machine.

Roughing cuts should be as heavy as the machine can

take; finishing cuts are usually 0.0005 inch or less. For

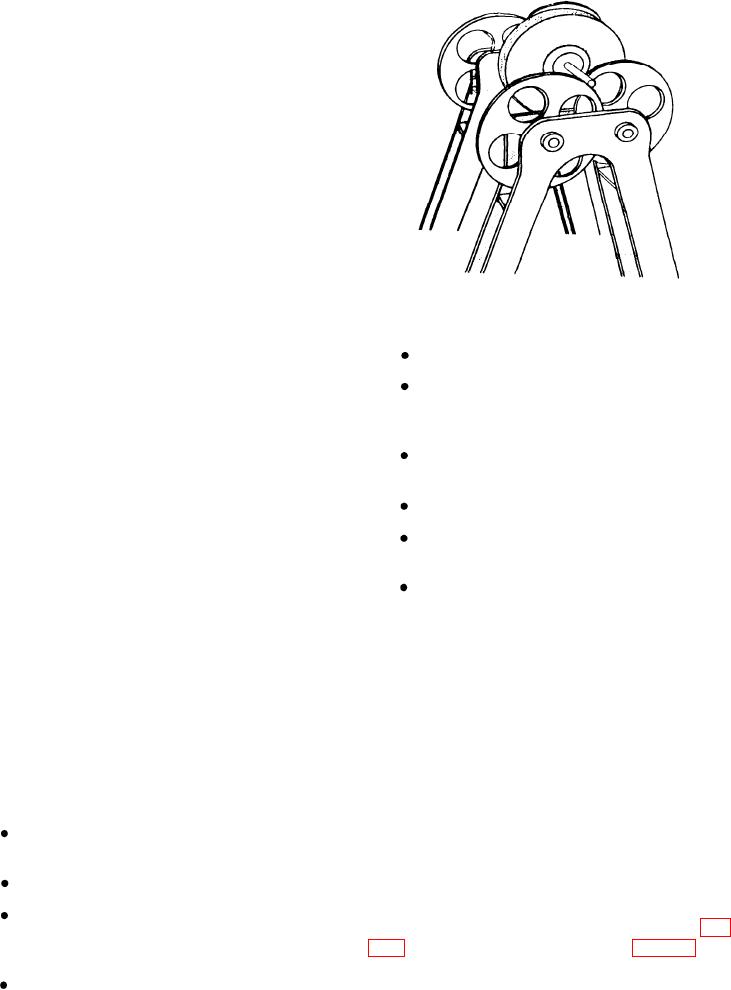

Figure 10-4.--Overlapping disk balancing ways (roller type).

as a trial. Then, adjust the machine until you get the best

cutting action.

Not cause rust or corrosion

Have a low viscosity to permit gravity separation

The cutting fluids used in grinding operations are

of impurities and chips as it is circulated in the cooling

the same as hose used in other machine tool operations.

system

Synthetic coolants are the best, but you also may use a

Not oxidize or form gummy deposits that will

mixture of soluble oil and water. As in most machining

clog the circulating system

operations, the coolant helps to maintain a uniform

temperature between the tool and the work to prevent

Be transparent, allowing a clear view of the work

extreme localized heating. Excessive heat will damage

Be safe, particularly in regard to fire and accident

the edges of cutters, cause warpage, and may cause

hazards

inaccurate measurements.

Not cause skin irritation

In other machine tool operations, the chips will fall

aside and present no great problem; this is not true in

The principles discussed above are basic to

grinding work. If you have no way to remove chips, they

precision grinding machines. Keep them in mind as you

can become embedded in the face of the wheel. This

study about the machines in the remainder of this

embedding, or loading, will cause unsatisfactory

chapter.

grinding and you will need to dress the wheel

frequently. A sufficient volume of cutting fluid will

help prevent loading. The fluid also helps to reduce

friction between the wheel and the work and to produce

WHEEL BALANCING

a good finish. When you select a cutting fluid for a

You may need to balance wheels larger than 14

grinding operation, it should have the following

inches, but usually not smaller ones. A wheel that is

characteristics:

slightly out of balance may cause chatter marks in the

Have a high cooling capacity to reduce cutting

workpiece finish. One that is drastically out of balance

temperature

may damage the grinder or fly apart and injure the

operator.

Prevent chips from sticking to the work

You should balance grinding wheels on either the

Be suitable for a variety of machine operations

overlapping disk balancing ways (roller type) (fig.

on different materials, reducing the number of cutting

fluids needed in the shop

these stands as level as possible, mount the wheel on a

Have long life and not emit obnoxious odors or

balancing arbor, and place it on the rollers or ways. The

vapors harmful to personnel

heavy side will rotate to the lowest position. Adjust

10-4