Figure 10-5.--Parallel ways (knife edge).

Figure 10-7.--Surface grinder (planer type).

sliding tables. This smooth, direct power is very

advantageous in grinding. The piping from this unit is

usually connected to power cylinders under the traverse

table. When the machine is operating automatically,

control valves divert pressurized hydraulic fluid to the

proper cylinder, causing the table to move in the desired

direction. Suitable bypass and control valves in the

hydraulic system let you stop the traverse table in any

position and regulate the speed of movement of the table

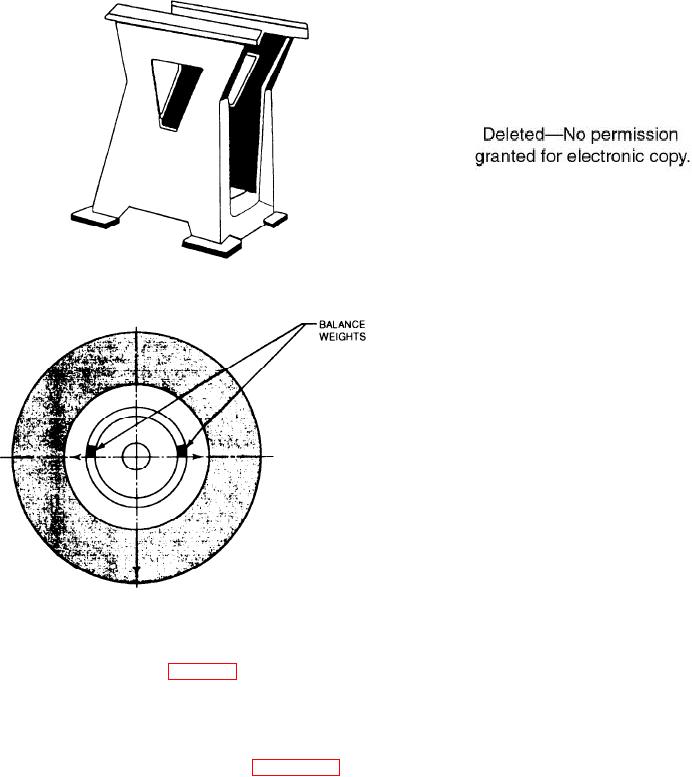

Figure 10-6.--Balance weights.

within limits. These valves provide a constant pressure

in the hydraulic system, allowing you to stop the feed

without securing the system.

balance.

CROSS TRAVERSE TABLE

SURFACE GRINDER

The cross traverse table is mounted on ways that are

parallel to the spindle of the wheelhead unit. This allows

the entire width of the workpiece to be traversed under

common to all planer-type surface grinders. The basic

the grinding wheel.

components of this machine are a base, a cross traverse

A piston in a power cylinder is fastened to the cross

table, a sliding worktable, and a wheelhead. Various

traverse table to provide power feed. A handwheel

controls and handwheels control the movement of the

attached to a feed screw provides manual feed. The

machine during the grinding operation.

thickness (width) of the grinding wheel determines the

The base is a heavy casting that houses the

amount of cross traverse feed per stroke of the

wheelhead motor, the hydraulic power feed unit, and the

reciprocating sliding table. During roughing cuts, the

coolant system. Use the ways on top of the base to

work should traverse slightly less than the thickness of

mount the cross traverse table. Use the vertical ways on

the wheel each time it passes under the wheel. For finish

the back of the base to mount the wheelhead unit.

cuts, decrease the rate until you obtain the desired finish.

The hydraulic power unit includes a motor, a pump,

When you engage the power feed mechanism, the cross

and piping. These provide hydraulic pressure to the

traverse table feeds only at each end of the stroke of the

power feed mechanisms on the cross traverse and

10-5