28.252

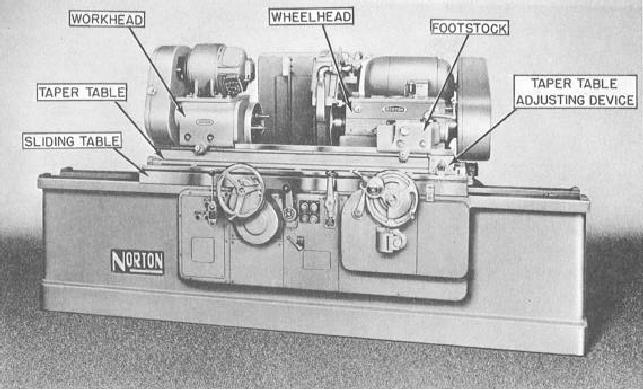

Figure 10-11.--Cylindrical grinder (with workhead and footstock mounted).

CYLINDRICAL GRINDER OPERATION

on the workpiece. Adjust the taper table like the taper

attachment on a lathe. Clamp workholding devices on

The methods used to set up stock in a cylindrical

top of the taper table.

grinder are similar to the methods used to set up lathes.

The motor-driven workhead is mounted on the

If you plan to grind work between centers, you will

taper table. This component holds and rotates the work

usually machine it to approximate size between centers

during the grinding cut. To meet the requirements of a

on a lathe. Then, you will use the same center holes for

job, you may need to change the speed at which the

the grinding setup. Use center rests or steady rests (as

workpiece rotates. The workhead has variable-speed

applicable) to support long work or overhanging ends.

drive motors or step pulleys for this purpose.

You can hold short workpieces in chucks. If you need

to do internal grinding (on machines that have an

You may use a chuck, a center, or a faceplate to

internal grinding spindle), hold the work in a chuck and

mount work on the workhead. You also may use center

use steady rests for any necessary support.

rests and steady rests in conjunction with the workhead

to mount long workpieces for cylindrical grinding.

When you set up a workpiece to grind between

centers, use the following procedures:

On most cylindrical grinders used by the Navy, the

workhead is mounted on a swivel base. This allows you

1. Be sure the centers in the workhead and

to set the work to grind relatively large taper angles.

footstock and the center holes in the workpiece are in

good condition.

WHEELHEAD

2. Clamp a driving dog onto the workpiece.

The wheelhead of a cylindrical grinder moves on

3. Position the workhead and footstock and set

the horizontal ways (platen). Since cylindrical grinding

the traverse stop dogs so that when the workpiece is in

is done with the axis of the spindle level with the center

place, the table will traverse (longitudinally) the proper

of the work, there is no need for vertical movement of

distance to grind the surface.

the wheelhead. Some wheelheads are mounted on

4. Make sure the workhead swivel, the taper table

swivel bases to provide versatility in taper and angle

attachment, and the wheelhead swivel are set properly

grinding setups.

10-9