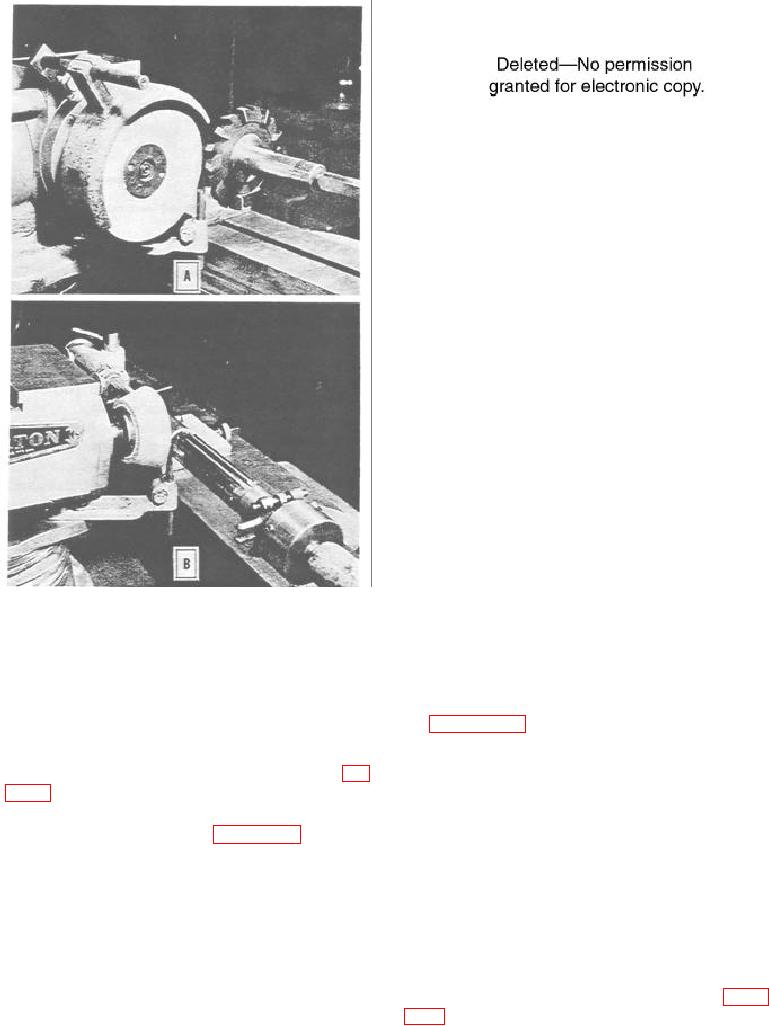

Figure 10-14.--Direction of wheel rotation. A. Toward the cutting

edge. B. Away from the cutting edge.

quick visible guide to show you the amount of

movement of the various feed components.

CUTTER SHARPENING

The working efficiency of a cutter is largely deter-

mined by the keenness of its cutting edge. Therefore,

you should sharpen a cutter at the first sign of dullness;

this practice is both economical and a sign of good

workmanship. A dull cutter not only leaves a poorly

finished surface, but also may be damaged beyond

repair if you continue to use it in that condition. Here is

a good rule to help you decide when to sharpen a cutter;

sharpen it when the wear land on the cutting edge is

between 0.010 and 0.035 inch.

Cutters to be sharpened may be divided into two

groups: (1) those that are sharpened on the relief and

(2) those that are sharpened on the face. The first group

includes cutters such as plain milling, side milling,

28.253A

stagger tooth, angle, and end nulls. The second group

Figure 10-13.--Tool grinding setups on a tool and cutter grinder.

A. Straight wheel grinding a milling cutter. B. Cup wheel

includes the various form cutters such as involute gear

grinding a reamer.

cutters and taps. The manufacturer provides the relief

on the second type of cutter by grinding the faces of the

teeth to sharpen them.

Also, the spindle is double ended, allowing you to

mount two wheels on the wheelhead.

cylindrical cutting tools on a tool and cutter grinder.

The basic workholding devices used on the tool and

View A shows a setup to grind a staggered tooth cutter

cutter grinder are the workhead and the footstock (fig.

using a straight wheel. View B shows a setup to grind a

10-12). When there is no workhead, you can use a

reamer using a cup type wheel. You can use either type

left-hand footstock similar to the right-hand footstock

of wheel; the cup-type produces a straight clearance

angle; the straight wheel produces a hollow ground

will have a variety of tooth rests to support and guide

clearance angle.

the teeth of a cutter being sharpened.

When you use the straight wheel, set the spindle

Most tool and cutter grinders have control

parallel to the table. When you use a flaring cup wheel,

handwheels at both the back and the front of the

turn the spindle at an angle of 89 to the table. This

machine. These dual controls permit you to stand in the

provides the necessary clearance for the trailing edge of

most convenient position to view the work while you

the grinding wheel as it is traversed along the cutter.

operate the machine. You can usually disengage the

When you grind a cutter, you should have the

sliding table handwheel to push the table back and forth

grinding wheel rotating as shown in view B of figure

by hand. Graduated collars on the handwheels offer a

10-14. This method tends to keep the tooth of the cutter

10-11