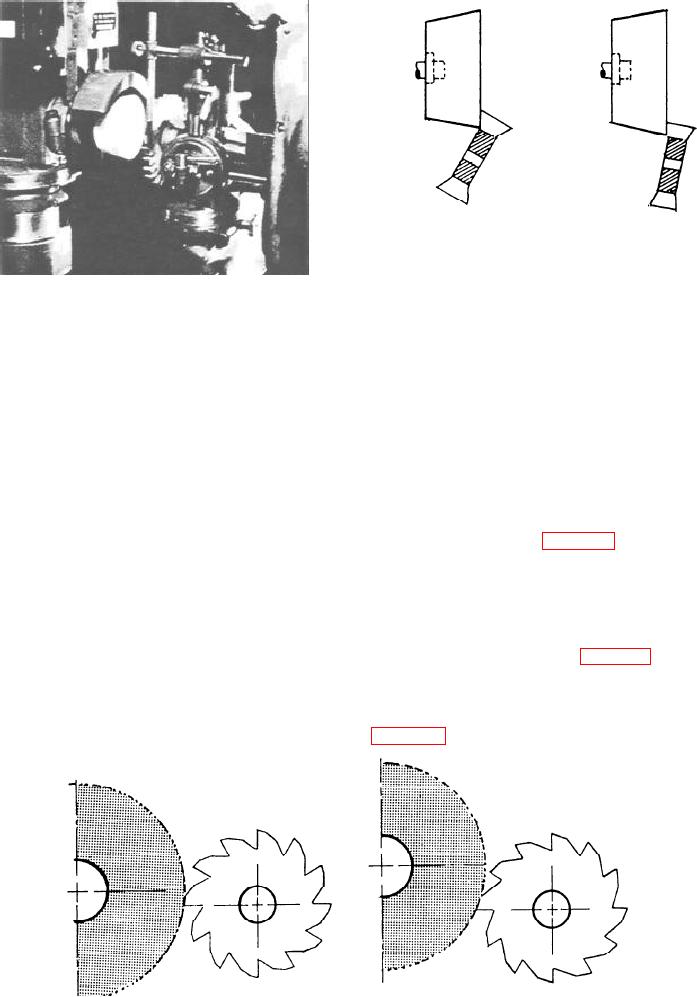

Figure 10-21.--Changing clearance angle by swiveling the cutter

in a vertical plane.

primary land, double the clearance angle and grind a

Figure 10-20.--Grinding the side teeth of a side milling cutter.

secondary land.

Before you start the sharpening operation, run

Side Milling Cutters

through it without the machine running. This will let

The peripheral teeth of a side milling cutter are

you get the feel of the machine and assure you that there

ground in exactly the same manner as the teeth of a plain

is nothing to obstruct the grinding operation. Traverse

milling cutter, with the exception that you will use a

the table with one hand and use the other hand to hold

plain tooth rest blade.

the cutter against the tooth rest blade. On the return

To sharpen the side teeth, mount the cutter on a stub

movement, the tooth rest blade will cause the mandrel

arbor and clamp the arbor in a universal workhead.

Then, mount a universal tooth rest holder onto the

to turn in your hand; this eliminates the need to move

workhead so that when the workhead is tilted the tooth

the table away from the wheel on the return traverse.

To sharpen the teeth of any milling cutter, grind one

The procedure used to grind clearance angles

tooth; then rotate the cutter 180 and grind another

varies, depending on the type of grinding wheel used.

tooth. Check the teeth with a micrometer to be sure you

If you are using a cup wheel, swivel the workhead

are not grinding a taper. If there is taper, you must

vertically to move the tooth toward or away from the

remove it by swiveling the swivel table of the machine.

wheel. The clearance angle increases as the tooth is

As the width of the land increases with repeated

sharpening, you will need to grind a secondary land on

a straight wheel, set the cutter arbor horizontally and

the cutter. Never allow the primary land to become

raise or lower the wheel to change the clearance angle.

greater than 1/16 inch wide, because the heel of the

The clearance angle increases as the wheel is raised

tooth may drag on the work To control the width of the

Figure 10-22.--Changing the clearance angle by raising the grinding wheel.

10-15