Once the teeth are uniform, they should remain uniform

HONING EQUIPMENT

through repeated sharpening because you will be taking

In honing, abrasive action does the cutting. You can

identical cuts on the cutting faces whenever you sharpen

use honing to remove stock from a drilled, bored,

the cutter.

reamed, or ground hole to correct taper, out-of-

roundness, or bow (bell-mouthed, barrel shape or

To sharpen a formed cutter using the formed cutter

misalignment). You can also use honing to develop a

sharpening attachment, attach the wheelhead shaft

highly smooth finish while accurately controlling the

extension to the shaft and mount a dish-shaped wheel

size of the hole.

on the extension. With the wheelhead swiveled to 90,

You may do cylindrical honing on a honing

clamp the attachment to the table with the paw1 side of

machine or on some other machine tool by attaching the

the attachment away from the wheel. Place the cutter on

honing device to the machine spindle, or you may do it

a stud and line up the cutting face of a tooth with the

by hand. Regardless of the method, either the hone or

attachment centering gauge. Loosen the paw1 locking

the work must rotate, and the honing tool must move

back and forth along the axis of rotation.

knob and adjust the paw1 to the back of the tooth. Then,

adjust the saddle to bring the face of the tooth in line

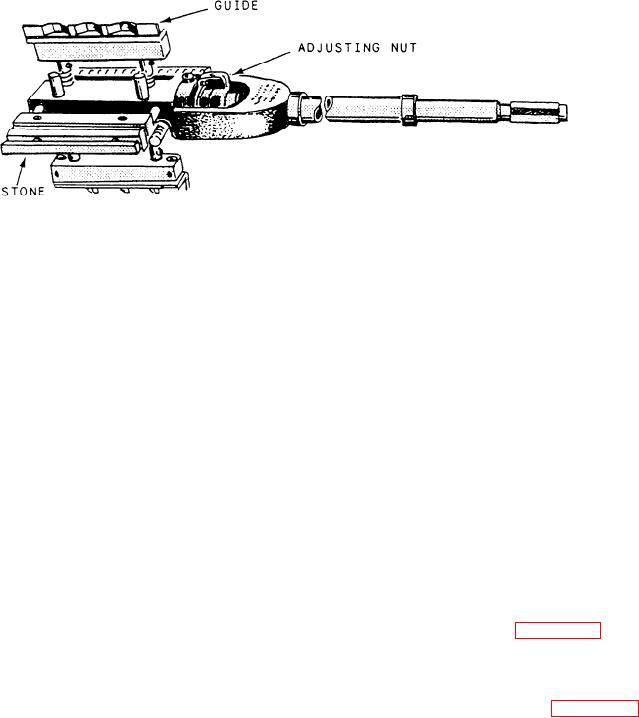

PORTABLE HONING EQUIPMENT

with the face of the grinding wheel. Once you have

made this adjustment, do not readjust the saddle except

to compensate for wheel wear. Grind one tooth, move

to the type used in most Navy machine shops. It is

the saddle away from the wheel, index to the next tooth,

normally available in sizes ranging from 1 3/4 to 36

and grind that one. If you grind all of the teeth once and

inches, and each hone set is adjustable to cover a certain

they have not been ground enough, rotate the tooth face

toward the wheel and make a second cut on each tooth.

two honing stones and two soft metal guides. The stones

and the guides advance outward together to maintain a

If a cutter has been initially provided with a radial

firm cutting action. An adjusting nut just above the

rake angle, this angle must be retained or the cutter will

stone and guide assembly is used to regulate the size of

not cut the correct form. To sharpen this type of cutter,

the honed bore. You can achieve accuracy to within

line up the point of one cutter tooth with the attachment

0.0001 inch when you follow the operating procedures.

gauge, swivel the table to the degree of undercut, adjust

To use the portable hone, follow these basic steps:

the saddle to bring the face of the tooth in line with the

1. Clamp the hone shaft in the drill press chuck.

face of the wheel, and grind.

2. Clamp the workpiece to the drill press table.

If you don't have a formed cutter sharpening

attachment, you can sharpen formed cutters by using a

3. Put the hone into the hole to be polished. Use

honing compound as required.

setup similar to that used to sharpen a plain milling

cutter--between centers on a mandrel. In this method,

4. Turn on the drill press and use the drill press feed

the setup used to grind a radial tooth formed milling

handle to move the rotating hone up and down in the

hole.

cutter is essentially the same as that used to grind a tap.

10-20