of an end mill, you change the size (diameter) of the

cutter. Therefore, you must show that the cutter size has

been changed. Either mark the new size on the cutter or

grind off the old size and leave the cutter unmarked.

Use the following steps to sharpen the end teeth:

1. Mount the end mill in a universal workhead.

2. Swivel the wheelhead to 89.

3. Use a centering gauge to bring the cutting edge

of a tooth into the same horizontal plane as the

wheelhead spindle axis. Place the gauge on top of the

wheelhead and raise or lower the wheelhead enough to

place the blade of the gauge on the tooth's cutting edge.

This also will align the cutting edge with the centerline

of the wheel.

4. Lock the workhead spindle in place to prevent

the cutter from moving.

5. Clamp the tooth rest blade onto the workhead so

that its supporting edge rests against the underside of

the tooth to be ground.

6. Swivel the workhead downward to the desired

clearance angle and clamp it in position. At this point,

make sure the tooth next to the one being ground will

clear the wheel. If it does not, raise or lower the

wheelhead until the tooth does clear the wheel.

7. Unclamp the workhead spindle and begin

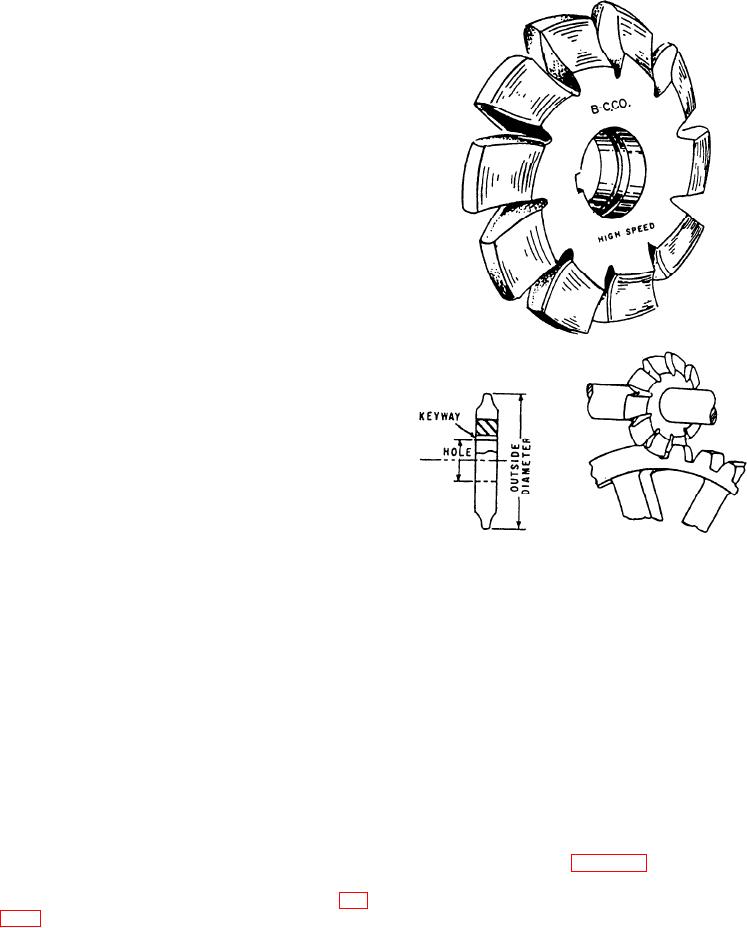

Figure 10-30.--Involute gear cutter.

grinding the mill.

8. After you have ground all of the primary lands,

center of the cutter. Turn the cutter until one of the teeth

tilt the workhead to the secondary clearance angle and

is horizontal; then raise the wheel until that tooth can be

grind all the secondary lands.

On end mills with large diameter wheels, it is often

a good idea to back off the faces of the teeth toward the

Formed Cutters

center of the cutter, similar to the teeth of a face mill.

An angle of about 3 is enough, allowing a land of 3/16

Two methods are commonly used to sharpen

to 5/16 inch long.

formed milling cutters. The first method uses a formed

You must use as much care when you grind the

cutter sharpening attachment and is by far the most

comers of the teeth as when you grind the faces of the

convenient. In the second, set up the cutter on a mandrel,

peripheral teeth. If not, the cutting edges will dull

grind the backs of the teeth, and then reverse the cutter

rapidly, and they will produce a poor finish. The comers

to sharpen the cutting faces.

of the teeth are usually chamfered 45 by swiveling the

workhead or table and are left 1/6 to 1/8 inch wide.

example. Since the teeth of these cutters have a specific

To sharpen the end teeth of a shell end mill (fig.

shape, the only correct way to sharpen them is to grind

10-29), mount the cutter on an arbor set in a taper shank

their faces. It is most important that the teeth are ground

mill bushing. Then, insert the bushing into the taper

uniformly and that they all have the same thickness

shank mill bushing sleeve held in the universal

from the back face to the cutting face. To get this

workhead. To get the desired clearance angle, swivel

uniformity, grind the back faces of all new cutters

the workhead in the vertical plane and swivel it slightly

before you use them. Grind only the back faces, since

in the horizontal plane to grind the teeth low in the

the cutting faces are already sharp and ready to use.

10-19