28.253

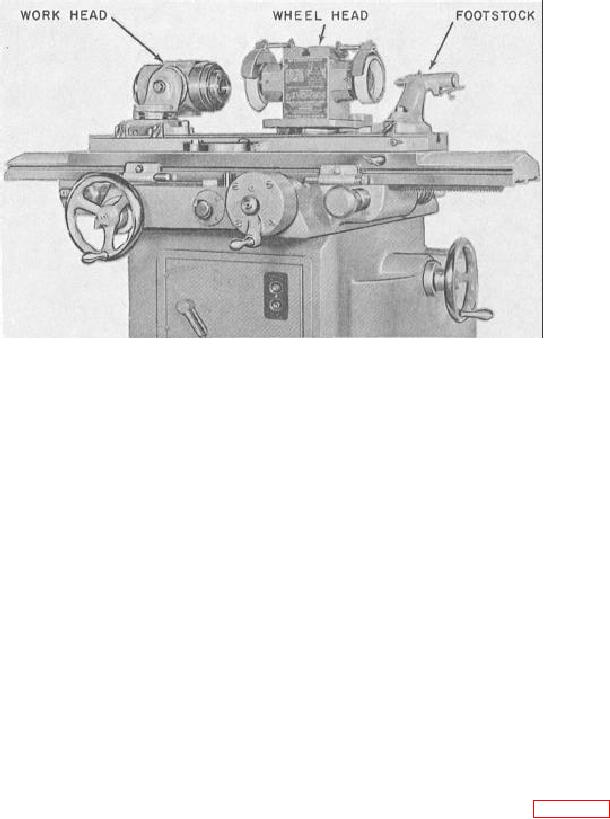

Figure 10-12.--Tool and cutter grinder (workhead and footstock).

11. Start the workhead motor and feed the grinding

for straight cylindrical grinding or for the correct taper

wheel in sufficiently to make a cleanup cut (a light cut

or angle, depending on the job.

the entire length of the surface to be ground).

5. Adjust the workhead speed mechanism to get

12. Using power longitudinal traverse, take a cut.

the proper rotational speed. Normally, you should use a

Then, disengage the power traverse, stop the workhead

slow speed for roughing and a high speed for finishing.

motor and wheelhead rotation, and check the workpiece

for taper. Make any changes required. (If you are using

6. Set the longitudinal traverse speed so the work

the taper table attachment and you need to make an

advances from two-thirds to three-fourths the thickness

adjustment at this point, dress the wheel again.)

of the wheel during each revolution of the workpiece.

We have not provided specific information on how

Use a fast traverse feed for roughing and a slow feed for

to set the various controls and speeds because there are

finishing.

variations for each machine. Look for this information

7. Set the workpiece in place and clamp the foot-

in the manufacturer's technical manual for your

stock spindle after making sure that both centers are

machine.

seated properly and that the driving dog is not binding.

TOOL AND CUTTER GRINDER

8. Select and mount the grinding wheel.

9. Start the spindle motor, hydraulic power pump,

combination of the features of the plain cylindrical

and coolant pump. After the machine has run for a few

grinder and the planer-type surface grinder. A tool and

minutes, start the coolant flow and dress the wheel.

cutter grinder is used primarily to grind multiedged

10. Using the cross traverse mechanism, bring the

cutting tools, such as milling cutters, reamers, and taps.

wheel up to the workpiece and traverse the table

The worktable has the same basic construction features

as the surface grinder, but a taper table is mounted on

longitudinally by hand to see that the wheel will travel

the sliding table so you can grind tools that have small

tapers, such as tapered reamers.

(About one-half of the wheel width should remain on

You can adjust the wheelhead in two directions. You

the work at each end of the longitudinal traverse stroke.)

can move it vertically on its support column through

Clamp the table dogs in the correct positions to limit

360. If you need to change the rotational direction of

longitudinal traverse.

the grinding wheel, simply rotate the wheelhead 180.

10-10