Figure 10-17.--A. Tooth rest blade in a plain holder. B. Tooth rest blade in a universal holder.

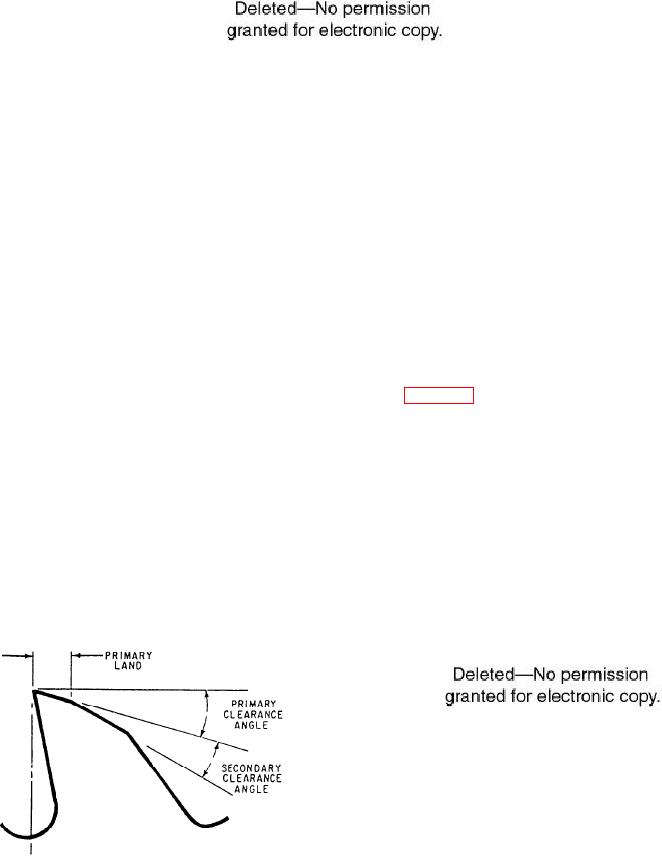

grind the primary clearance angle) varies according to

rest all in the same plane and then raise or lower the

the size of the cutter. Primary land widths range from

wheelhead the proper distance to give the desired

0.0005 to 0.015 inch for a small cutter to 0.030 to 0.062

clearance angle.

inch for a large cutter. You should grind the lands very

When you use the straight wheel, use a centering

carefully. A land that is too narrow will allow the cutting

edge to chip or wear rapidly. A land that is too wide will

of the wheel and the center of the work into the same

cause the trailing side (heel) of the land to rub the work.

plane. Then, fasten the tooth rest to the machine table

When the width of the primary land becomes

and adjust the tooth rest to the same height as the center

excessive due to repeated grindings, you must grind the

secondary clearance angle to reduce it. The secondary

clearance angle is normally 3 to 5 greater than the pri-

mary clearance angle.

You get the desired clearance angle by the

positioning of the grinding wheel, the cutter, and the

tooth rest. The general procedure is to position the

center of the wheel, the center of the work, and the tooth

Figure 10-18.--Cutter clearance angles.

Figure 10-19.--Centering gauge.

10-13