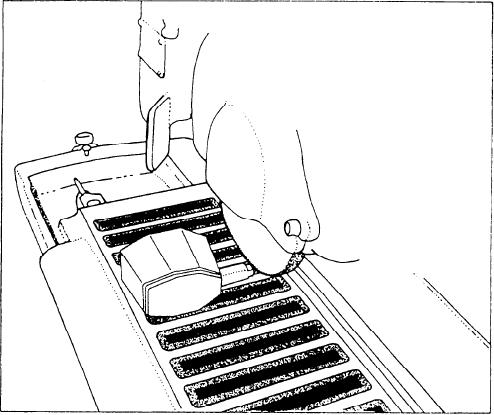

Figure 10-8.--Magnetic chuck used for holding a tool grinding fixture.

sliding table (discussed in the next paragraphs). The

is used, table reverse dogs reverse the direction of

grinding wheel clears the ends of the workpiece before

movement of the table at each end of the stroke. The

cross-feed is made; this decreases side thrust on the

reverse dogs actuate the control valve to shift the

grinding wheel and prevents a poor surface finish on the

hydraulic feed pressure from one end of the power

ends of the workpiece.

cylinder to the other.

Grinding machines in shipboard shops usually have

You can usually adjust the speed (fpm) of the sliding

12 inches or less of cross traverse. It isn't necessary to

table within a wide range to give the most suitable

traverse the full limit for each job. To limit the cross

speed.

traverse to the width of the work being ground, use the

adjustable cross traverse stop dogs that actuate the

WHEELHEAD

power cross traverse control valves.

The wheelhead carries the motor-driven grinding

SLIDING TABLE

wheel spindle. You can adjust the wheelhead vertically

to feed the grinding wheel into the work by turning a

The sliding table is mounted on ways on the top of

lead screw type of mechanism similar to that used on

the cross traverse table. Recall that the sliding table

the cross traverse table. A graduated collar on the

moves from left to right, carrying the workpiece under

handwhcel lets you keep track of the depth of cut.

the grinding wheel.

The wheelhead movement is not usually power fed

The top of the sliding table has T-slots machined in

because the depth of cut is quite small and you need

it so you can clamp work or workholding devices like

large movement only to set up the machine. The

magnetic chucks or vises onto the table. You can

adjusting mechanism is quite sensitive; you can adjust

traverse the sliding table manually or by power.

the depth of cut in amounts as small as 0.0001 inch.

The power feed of the table is similar to that of the

cross traverse table. During manual traverse, a pinion

WORKHOLDING DEVICES

turned by a handwheel engages a rack attached to the

bottom of the sliding table.

During manual operation of the sliding table, table

In most surface grinding operations, you will use

stop dogs limit the length of stroke. When power feed

one of two workholding devices, either a magnetic

10-6